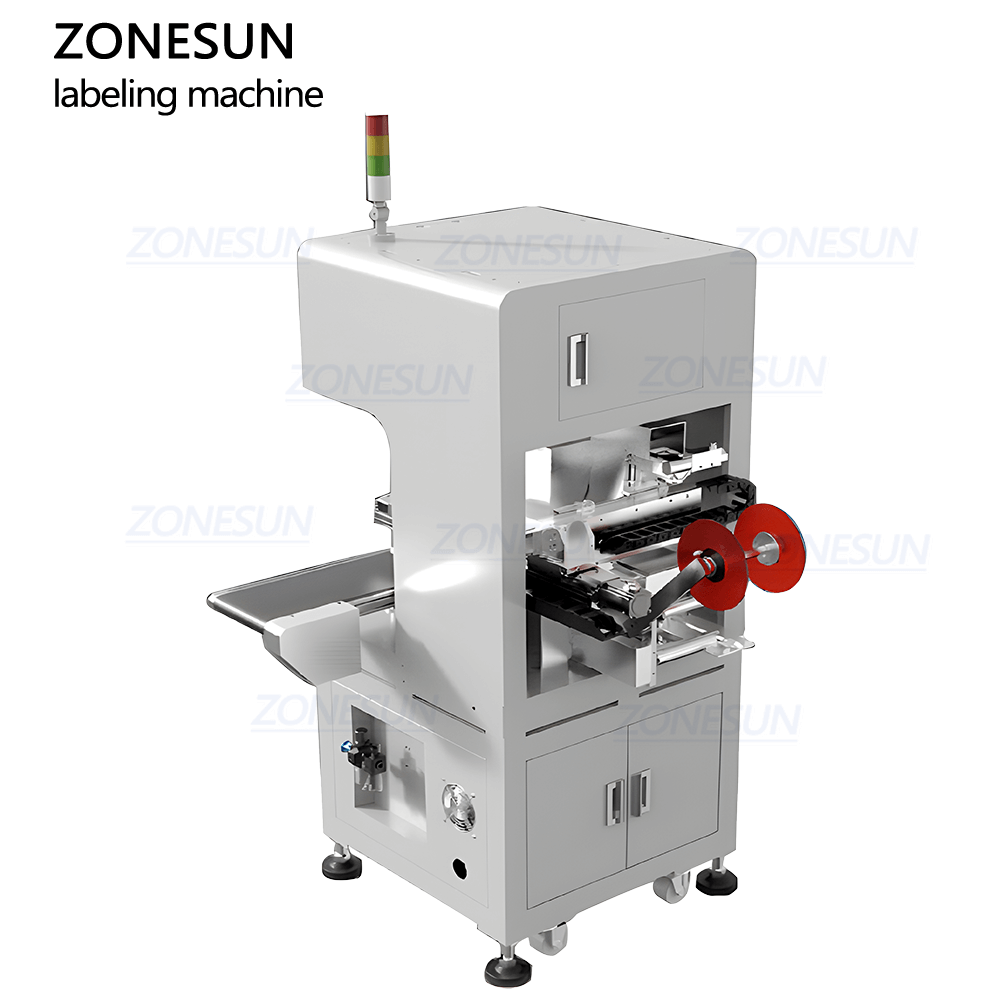

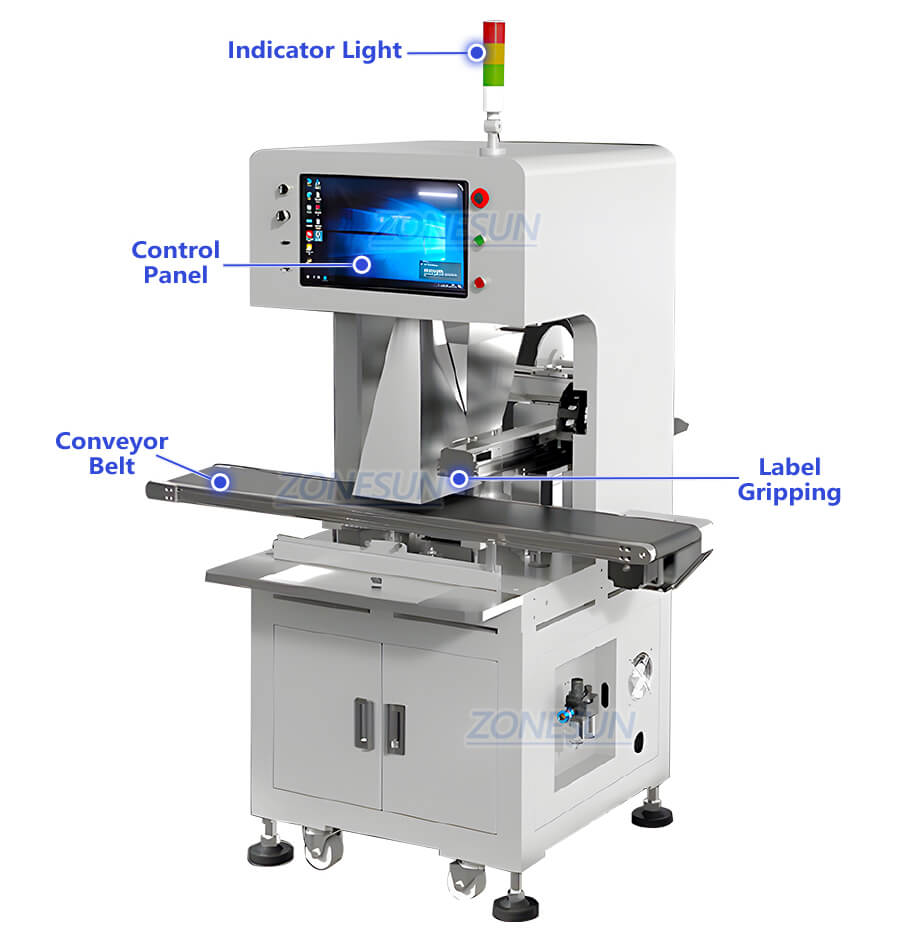

CCD Dual Vision Inspection Flat Labeling Machine

Product Description:

The Visual Inspection Labeling Machine with Feeder and Accumulator is a comprehensive solution for automated labeling of flat objects, designed for high-volume production lines. This machine features an integrated feeder system to automatically feed products into the labeling area, followed by a vision inspection system that accurately identifies the product’s position and orientation. The labeling head then precisely applies labels to the specified location. Finally, an accumulator system collects the labeled products, ensuring a smooth and efficient workflow.

Product Parameters:

| Model | ZS-STB2 |

| Capacity | 20-30 pieces/min |

| Labeling Accuracy | ±0.5MM (excluding product error) |

| Machine Dimensions | About 1500*700*1700mm |

| Machine Weight | About 350kg |

| Applicable Product Size | Width≥450MM |

| Applicable Label | Width≥250MM |

| Power Supply | 220V/50HZ |

| Power Consumption | 1200W/AC220V |

| Air Pressure | 0.4-0.6MPA |

Product Details:

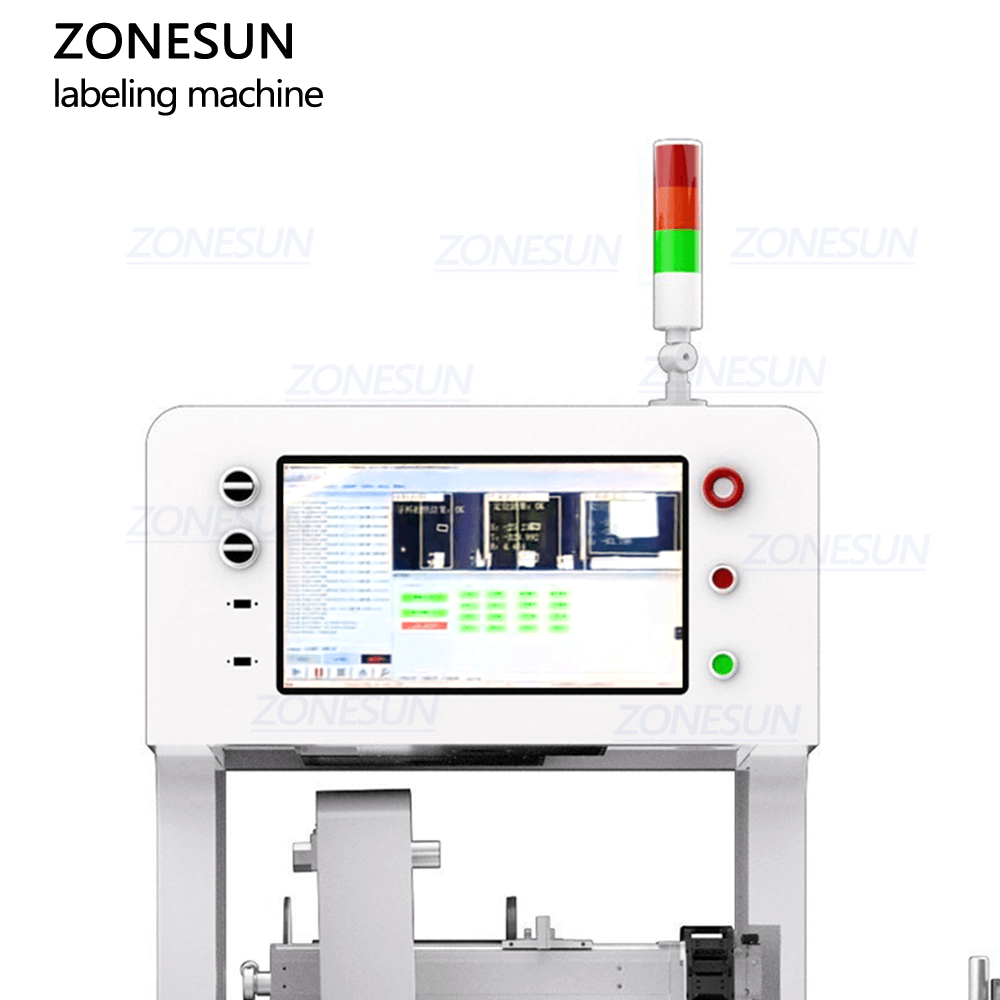

User-Friendly Interface

Adopting imported PLC touch screen, easy and fast operation, adjustable frequency conversion technology.

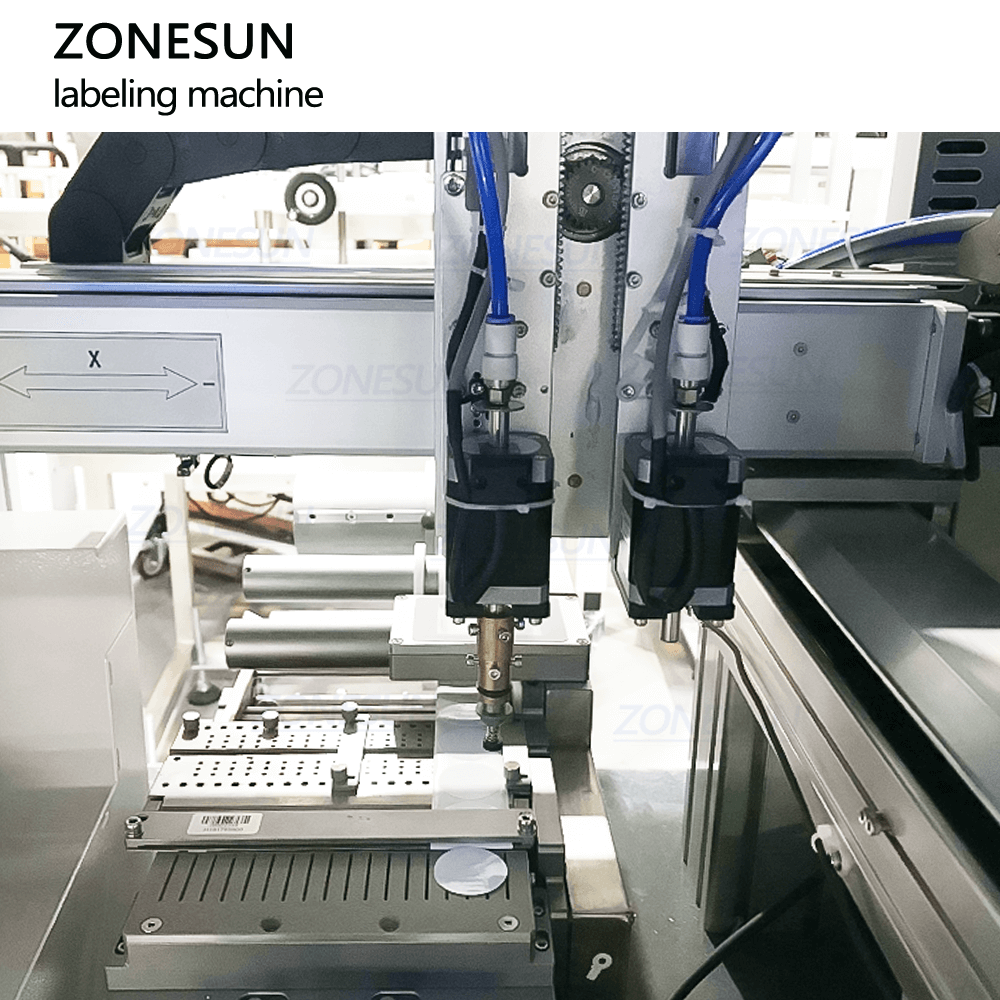

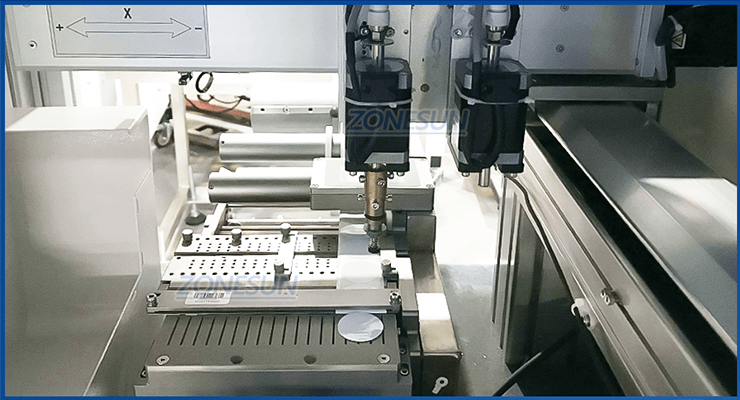

High Precision

Engineered for meticulous label placement, minimizing errors and enhancing overall product appearance.

High Speed & Efficiency

Delivers rapid label application, significantly increasing throughput and operational efficiency.

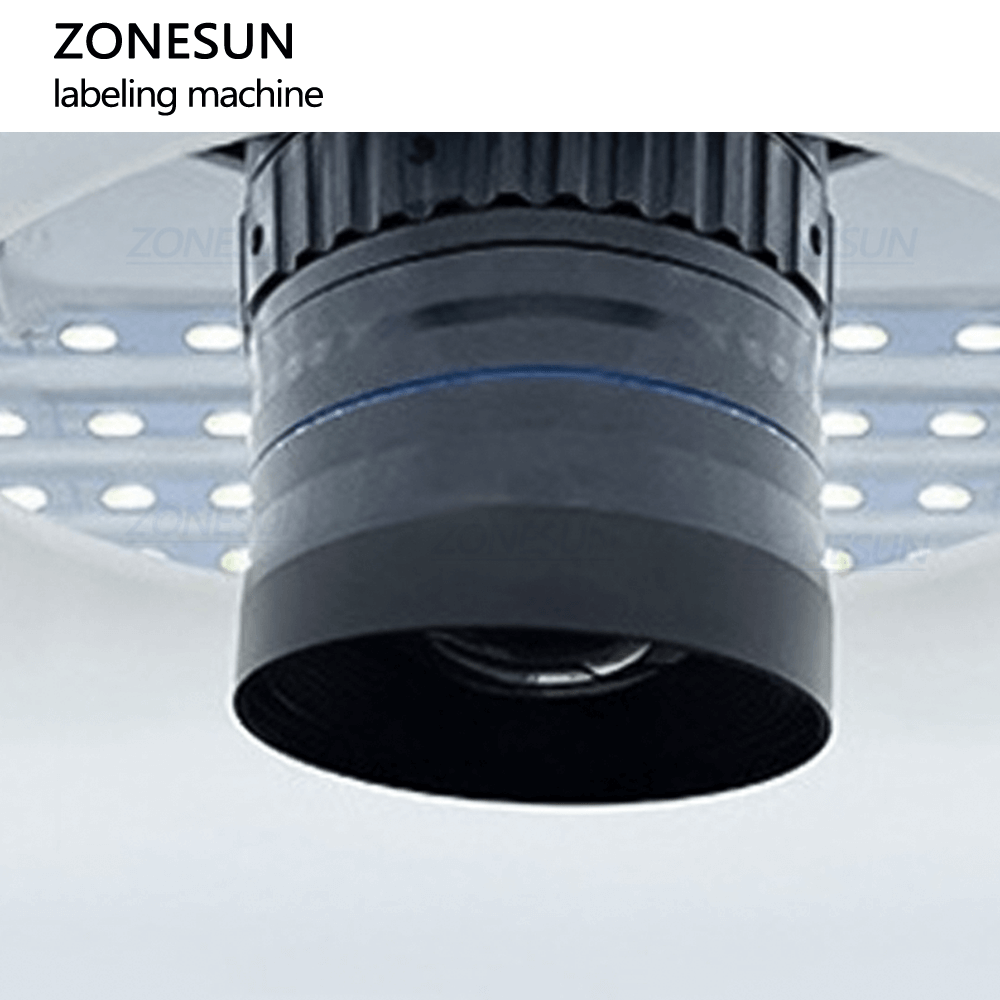

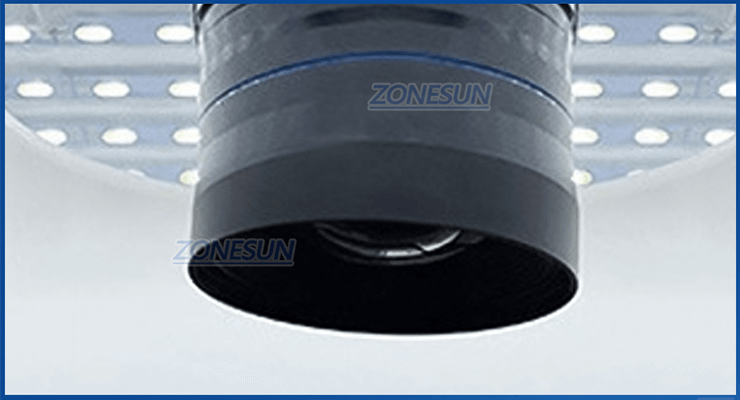

360-Degree View

Allows operators to monitor the labeling process from all angles, ensuring precise alignment.

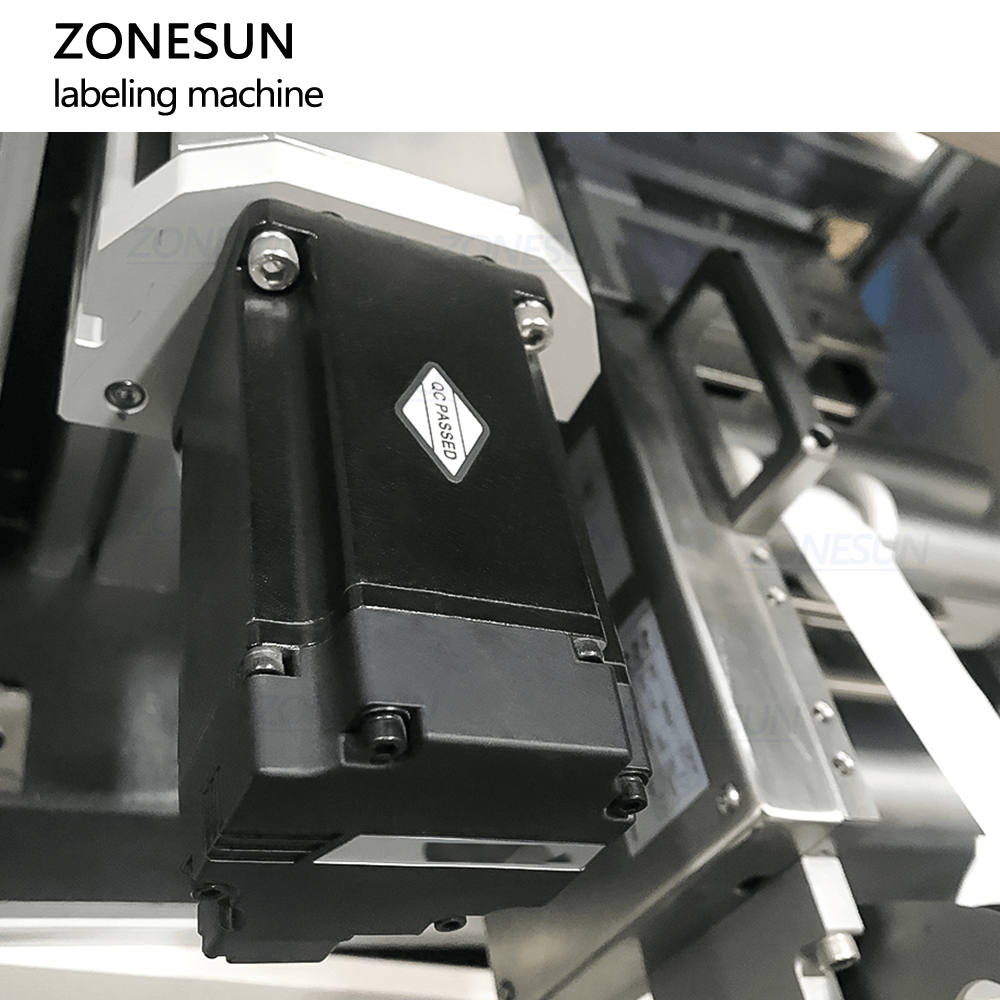

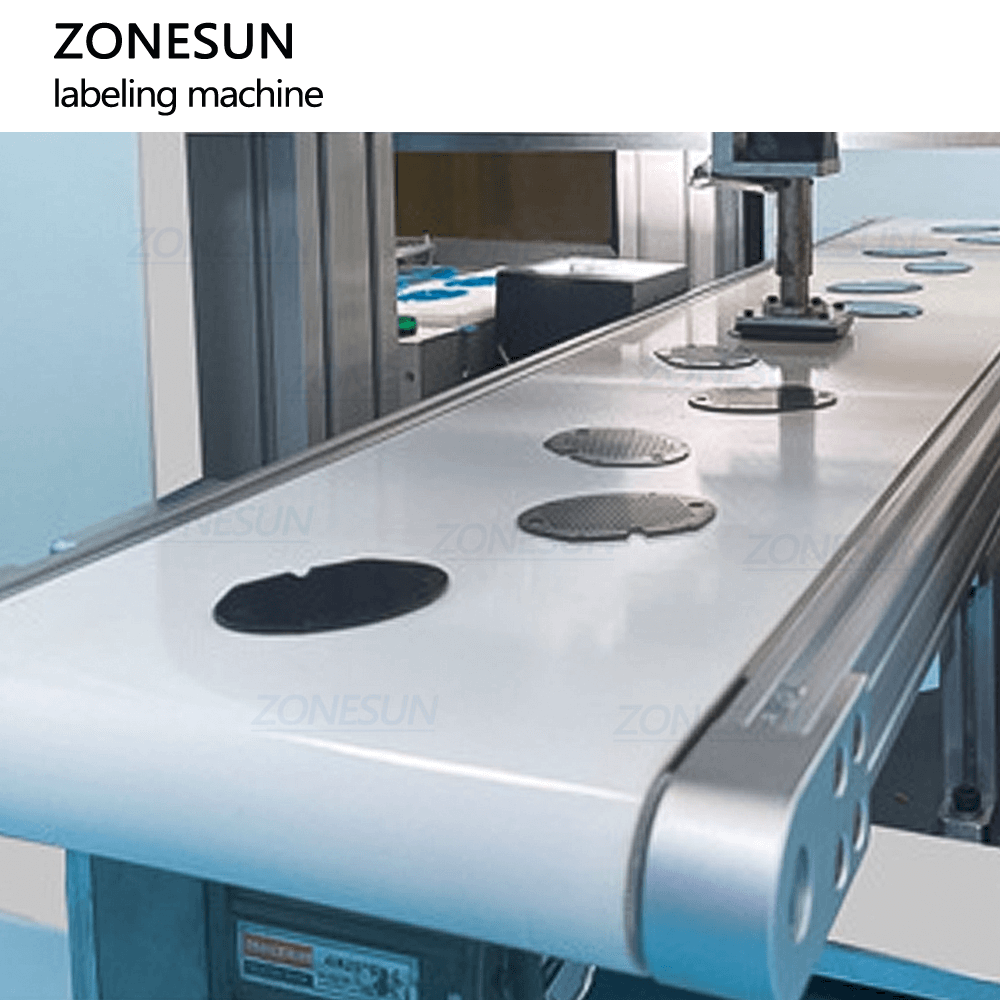

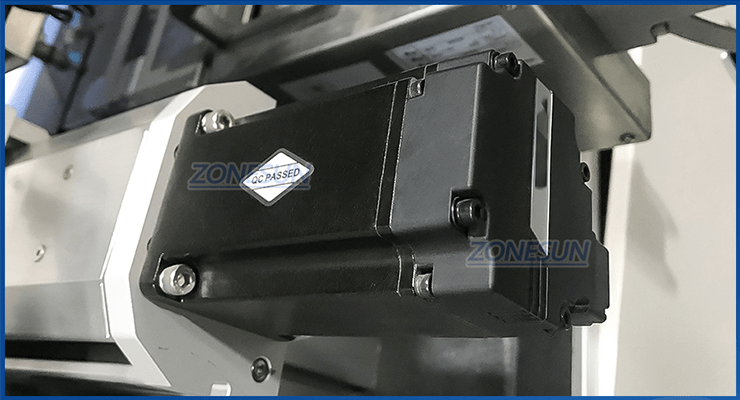

Stable and Reliable

Ensures smooth transport of products through the labeling process, further improving accuracy.