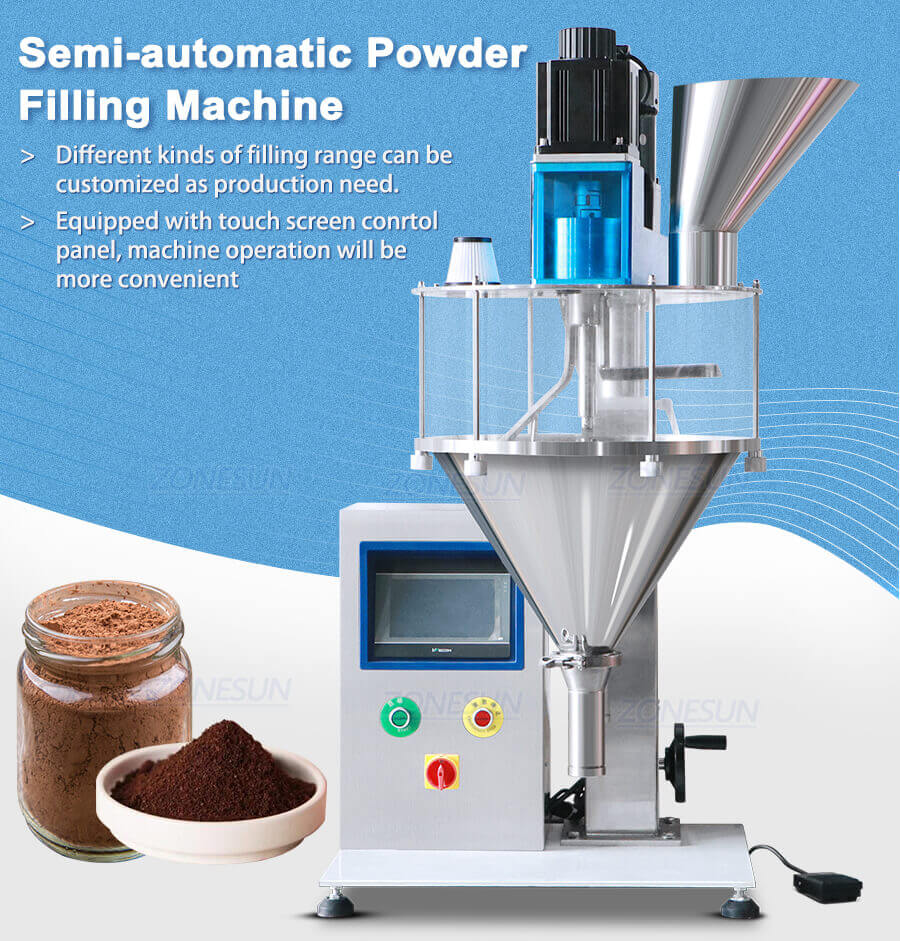

Desktop Cosmetic Powder Filling Machine

Product Description:

The semi-automatic powder filling machine is utilized in various industries like food processing, izimonyo, and chemicals. It fills containers with powdered substances and can be customized for different filling volumes. This machine is designed to enhance efficiency and accuracy in the filling process while minimizing manual labor.

Product Parameters:

| Imodeli yomshini | ZS-FM100B |

| Machine voltage | 110/220V 50-60HZ |

| Screw diameter & filling range | φ19mm 0.5-10g φ25mm 2-15g φ32mm 10-30g φ38mm 20-50g φ51mm 30-100g φ64mm 100-500g φ76mm 200-2000g (for reference only, it will be different according to filling material) |

| Hopper size | 35L(customized) |

| Hopper diameter | 450mm(customized) |

| Filling nozzle size | customized |

| Working capacity | 10-25 BPM(based on filling volume) |

| Container height | H≤300mm |

| Filling accuracy | ±1%(based on filling range) |

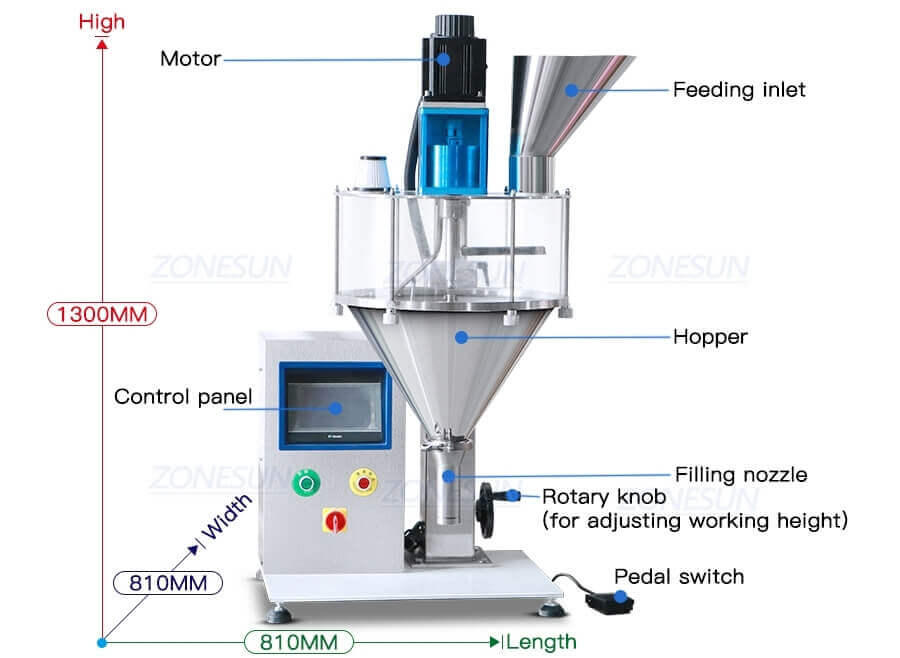

| Usayizi womshini | About 780*750*1150mm |

| Isisindo somshini | About 120kg |

| Usayizi wephakheji | About 810*810*1300mm |

| Isisindo sephakheji | About 144kg |

Product Details:

Touch screen panels can be tailored to various product requirements or production processes. They enable operators to adjust settings like fill volume and speed directly from the screen, eliminating the need for mechanical adjustments.

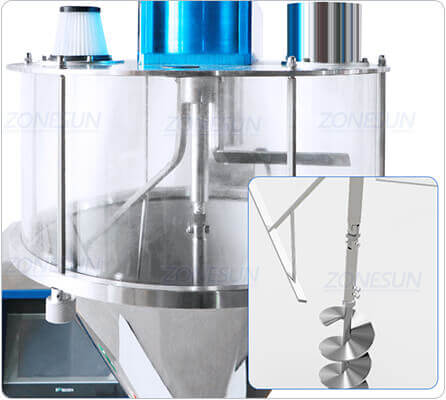

The hopper size can be tailored to your specific filling range requirements. This ensures ample storage capacity, allowing the powder filling machine to operate continuously for extended periods without the need for frequent interruptions to refill the material. The filling range of this machine can be customized to suit your production needs.

This machine utilizes intelligent control to ensure precise filling, preventing material waste. The size of the filling nozzle can be tailored to match the container diameter.

The machine's working height can be adjusted for optimal filling accuracy, depending on the size of the bottle, using a rotary knob.

The pedal switch allows for hands-free operation of the machine. It enables operators to activate or control the machine's functions using their foot, thus freeing their hands for other tasks like handling materials or adjusting settings.