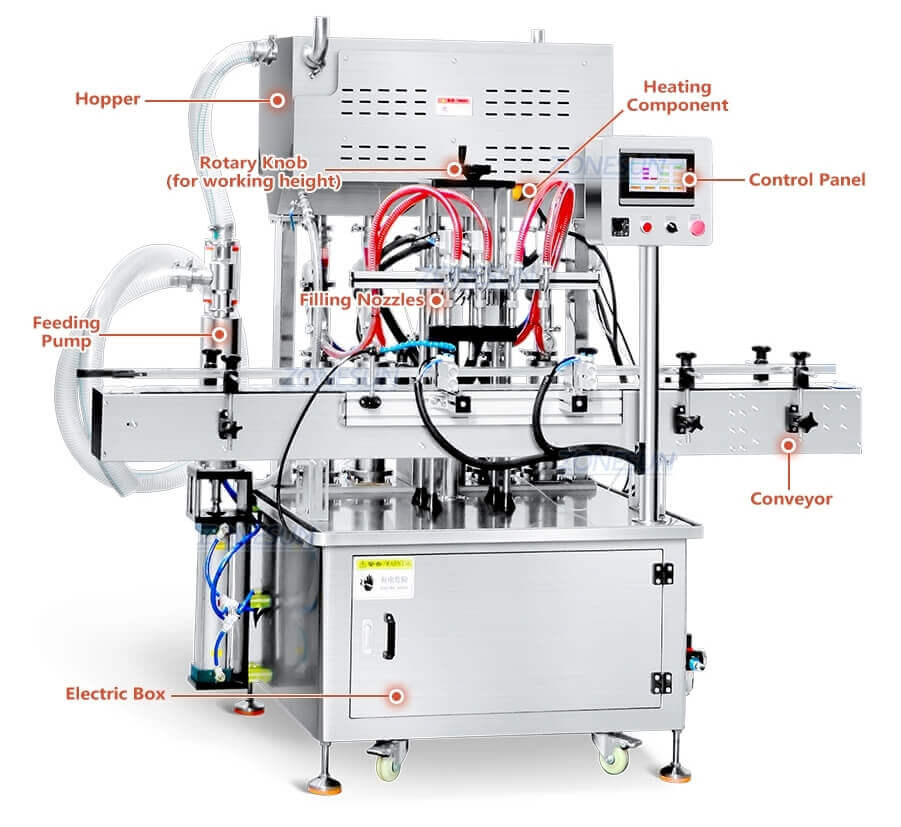

Sauce Paste Filling Vacuum Capping Machine

Product Description:

The filling production line consists of a piston pump filling machine and a steam vacuum capping machine. We can customize the heating and mixing function for your filling material pretreatment. This system is ideal for packaging hot sauce, honey, tomato sauce, and peanut butter.

Product Parameters:

| Awoṣe ẹrọ | ZS-YT4T-4PH |

| Foliteji | 110/220V 50-60HZ 1KW |

| Filling range | 10-180ml/30-500ml/100-1000ml |

| Iyara iṣẹ | About 30-50bottles/min |

| Àgbáye fifa | Piston pump |

| Air pressure | 0.6-0.8MPa |

| Suitable temperature range | 30≤T≤90℃ |

| Àgbáye išedede | ±1% |

| Filling Nozzle | 4(le ti wa ni adani) |

| Iwọn ẹrọ | About 2000*800*1800mm |

| Iwọn ẹrọ | About 200kg |

| Packaging size | About 2070*960*2010mm(100-1000milimita) |

| Packaging weight | About 392kg(100-1000milimita) |

| Awoṣe ẹrọ | ZS-XG01 |

| Ibi ti ina elekitiriki ti nwa | 220/380V 3.12KW |

| Working capacity | About 4000BPH |

| Suitable cap size | Adani |

| Suitable bottle size | Adani |

| Steam consumption | 180-230kg/h |

| Steam pressure | ≤0.4MPa |

| Maximum vacuum degree | 34-67KPa |

| Iwọn ẹrọ | About 3250*1050*2010mm |

| Iwọn ẹrọ | About 500kg |

Product Details:

The touch screen control panel can be tailored to various languages for user-friendly operation. Real-time visual data aids in quick machine adjustments.

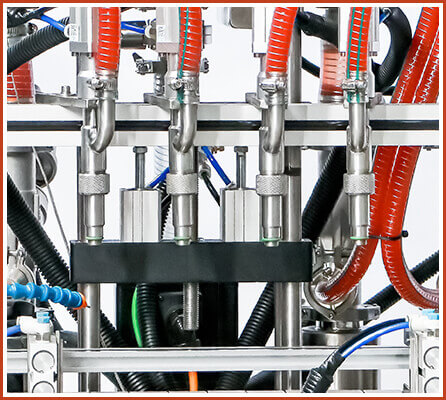

The filling nozzle can be adjusted to accommodate different bottle sizes. Additionally, the number of filling heads can be customized to optimize efficiency based on your production needs.

The filling machine comes with a heating function that keeps the products in a more fluid state, enhancing their flow properties. Additionally, we can customize an extra mixing function for the filling material pretreatment.

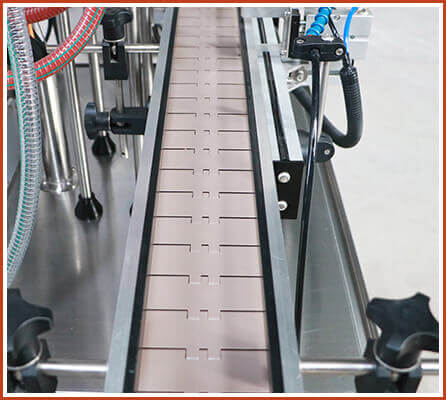

Constructed from a high-quality conveyor belt, our chain conveyor boasts a larger weight capacity, facilitating faster and smoother bottle transportation. We can customize the width and length to suit your operational needs.

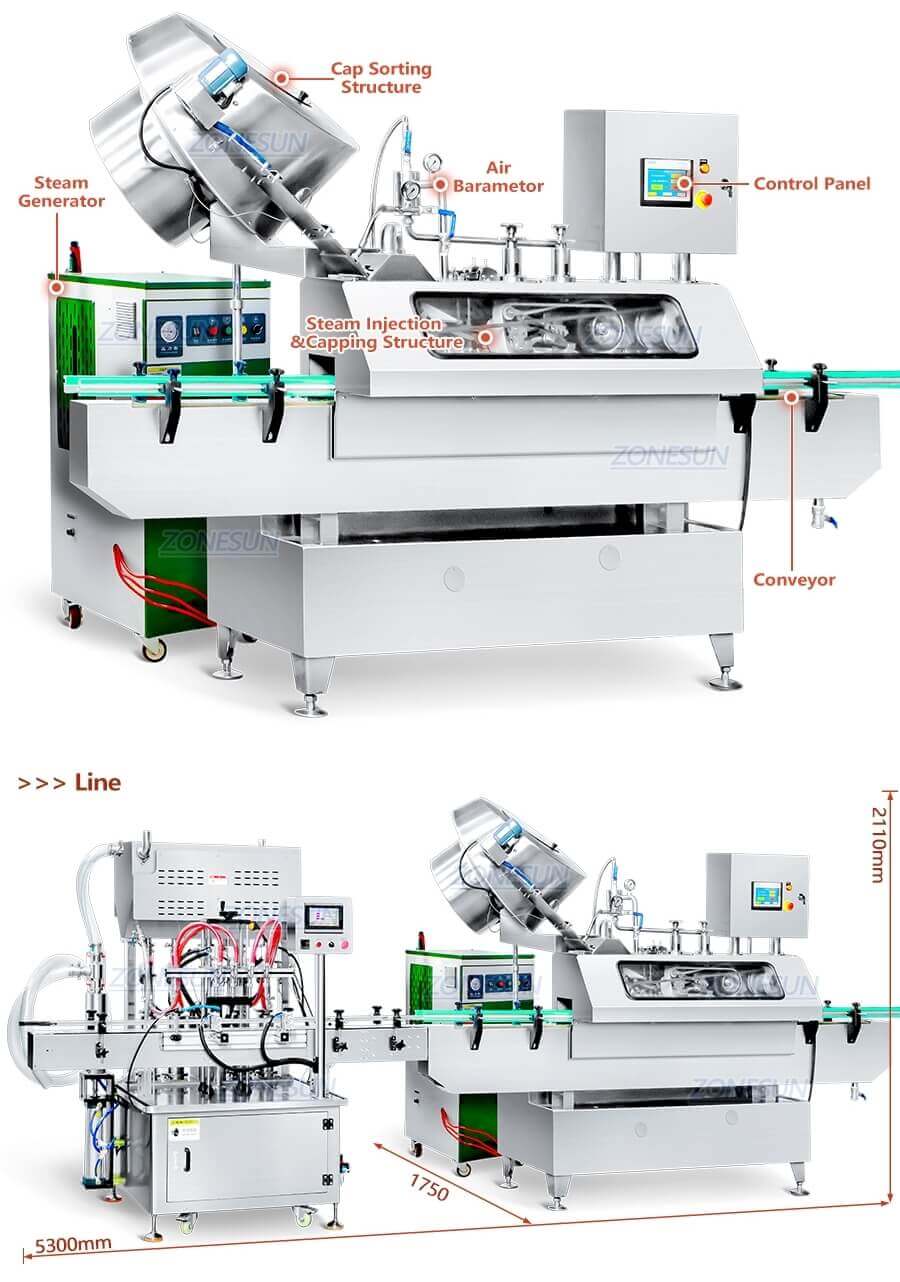

The machine operates with an electric rotation cover sorting method, resulting in lower noise and smoother cover sorting. This significantly enhances the efficiency of the machine.

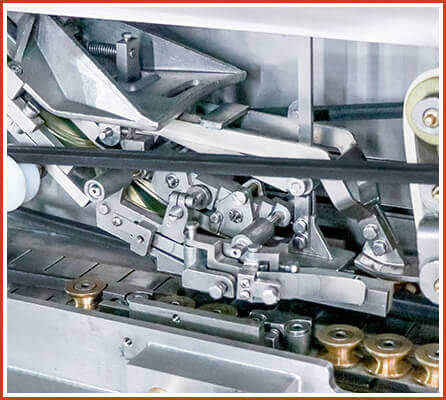

Before sealing, the bottle undergoes steam injection to replace the top space's air with high-speed steam. The cap is then tightened by two flat belts, ensuring both efficiency and packaging quality.

This vacuum capping machine is designed to function optimally when paired with a steam generator. The generator ensures a consistent supply of steam, guaranteeing uninterrupted and stable operation of the machine.