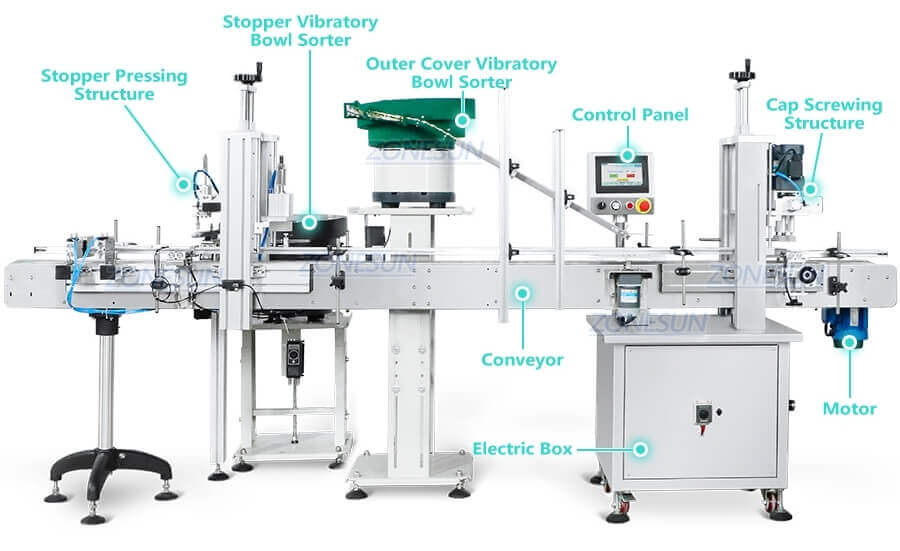

Otomatik Şişe Tıpa Presleme Kapağı Kapatma Makinası

Ürün Açıklaması:

This automatic bottle capping machine operates in two distinct structures. One section presses bottle stoppers, while the other caps outer covers. It's equipped with a vibratory bowl sorter to ensure stoppers and outer covers are in order before packaging. This machine is tailored for the daily chemical industry.

Ürün parametreleri:

| Makine modeli | ZS-XG16X |

| Çalışma gerilimi | 220V / 110V 50- 60HZ |

| Şişe yüksekliği | 30-300aa |

| Kapak çapı | 18-70aa |

| Şişe çapı | 20-160aa |

| Çalışma hızı | 10-25 şişe / dak(kapağın boyutuna ve şekline bağlı olarak) |

| Çalışma basıncı | 0.4-0.6MPa |

| Hava kompresörü konektörünün boyutu | OD 8mm |

| Paket Boyutu | About 1970*510*990mm(Stopper Pressing Machine)+2020*770*1750aa(Screw Capper) |

| Brüt ağırlık | Yaklaşık 104kg(Stopper Pressing Machine)+303kilogram(Screw Capper) |

Ürün Detayları:

The PLC control panel provides real-time display of working data, offering a more intuitive interface for machine operation. It can be tailored to accommodate various languages based on production requirements.

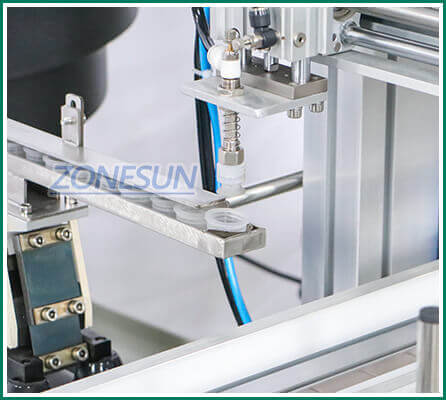

The air nozzles, controlled by an air cylinder, can maneuver light caps or stoppers onto bottle mouths like a human hand. This ensures high working accuracy.

Vibratory bowl sorting machines streamline the sorting process, reducing manual labor and boosting efficiency. They are tailored to specific stopper and cap sizes, ensuring high accuracy in operation.

The capping structure can be adjusted for different bottle cap sizes and shapes, making it suitable for various types of caps, including spray caps, dropper bottles, and sharp-pointed bottles.

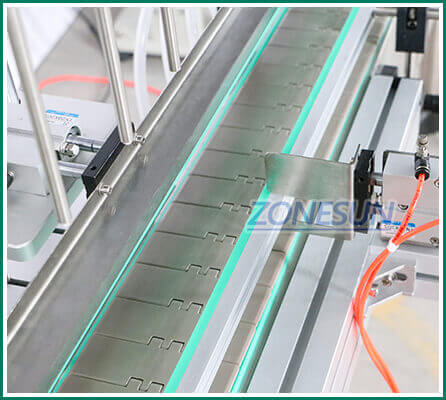

The chain conveyor can be tailored to your specific production requirements, ensuring it has a larger weight capacity and can transport products more efficiently and consistently.