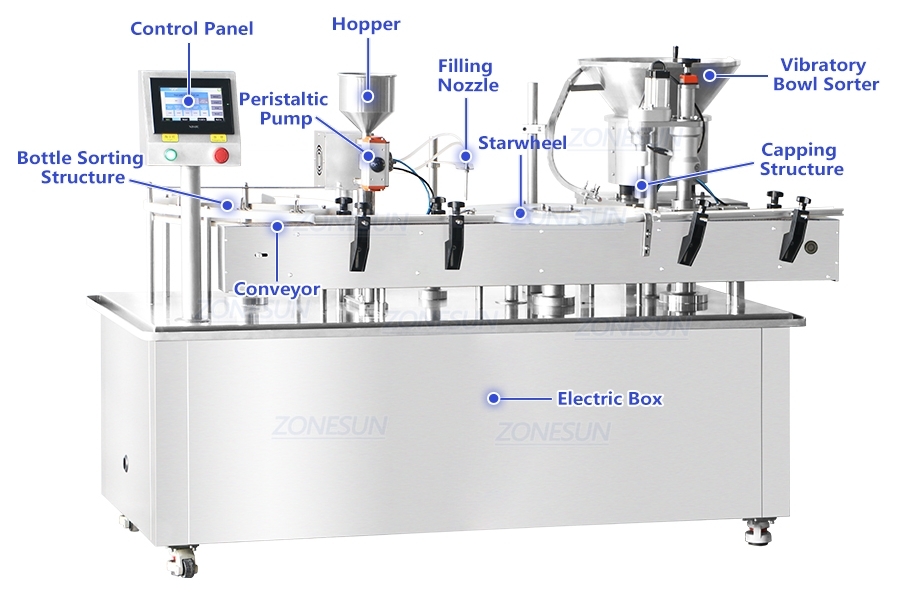

Машина для наполнения и укупорки лака для ногтей

Описание:

This monoblock machine is equipped with a peristaltic pump and a ceramic pump, making it ideal for small-volume mixtures requiring separate filling of paste and liquid, such as gel. You can choose to fill only paste or liquid. The capping chuck is customized based on cap size and controlled by a servo motor for high accuracy.

Параметры продукта:

| Модель машины | ZS-AFC30 |

| Напряжение машины | 110/220V 50-60HZ |

| ZONESUN ZS-XYZ4 Керамический плунжерный насос Высокоточная автоматическая машина для наполнения пробирок с реагентами 10 мл | Перистальтический насос&Керамический насос |

| Диапазон наполнения | 4мл(можно настроить) |

| Количество заправочных форсунок | 2(can be customized as needed) |

| Filling hose size | #17(can be chosen based on packaging requirement) |

| Точность заполнения | ± 1%(в зависимости от объема наполнения и материала) |

| Рабочая скорость | О 10-30 бутылок / мин(в зависимости от объема наполнения и материала) |

| Размер машины | About 2200*1400*1450mm |

| Размер посылки | About 2430*1230*1620mm |

| Вес упаковки | About 785kg |

информация о продукте:

The machine is equipped with a touch screen control panel, offering a customizable interface for enhanced convenience. The operating language can be tailored as per your requirements. The PLC control panel provides real-time data display.

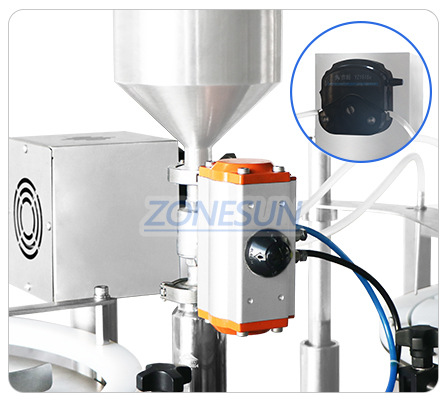

Equipped with ceramic pump and peristaltic pump. The hopper can make filling material can be filled more smoothly.These two pumps can work together for mixtures that require separate filling of paste and liquid or work separately to fill liquid or paste only.

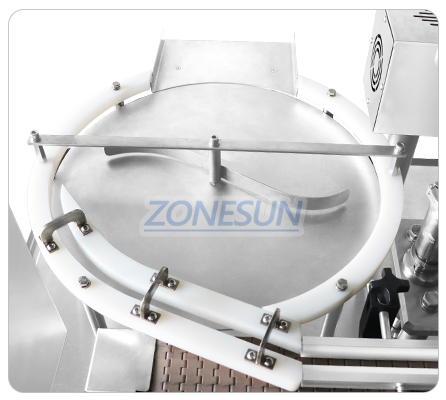

This machine is equipped with a bottle sorting structure, which simplifies operations and automatically arranges bottles in order, significantly saving on labor.

The filling and capping process is managed by a cam working system, enhancing efficiency and packaging precision. The starwheel's size is tailored to the bottle size, ensuring bottle stability during packaging.

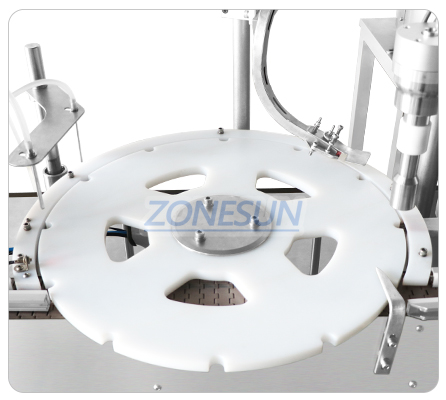

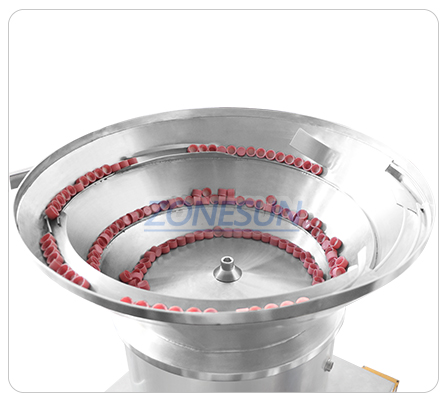

A customized vibratory bowl sorter can efficiently organize caps prior to capping and guide them through a rail, thereby reducing operational errors.