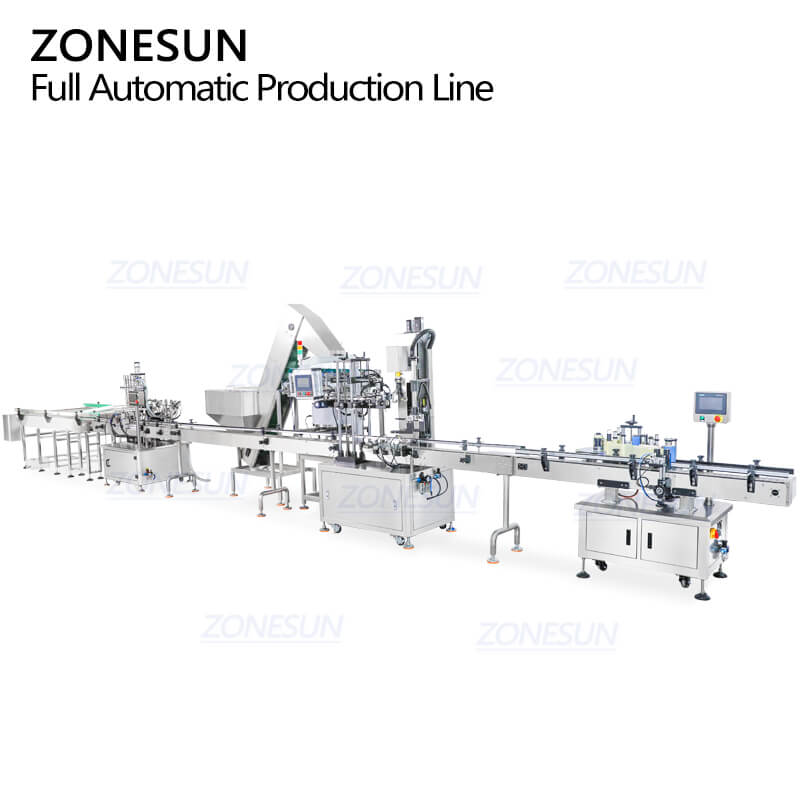

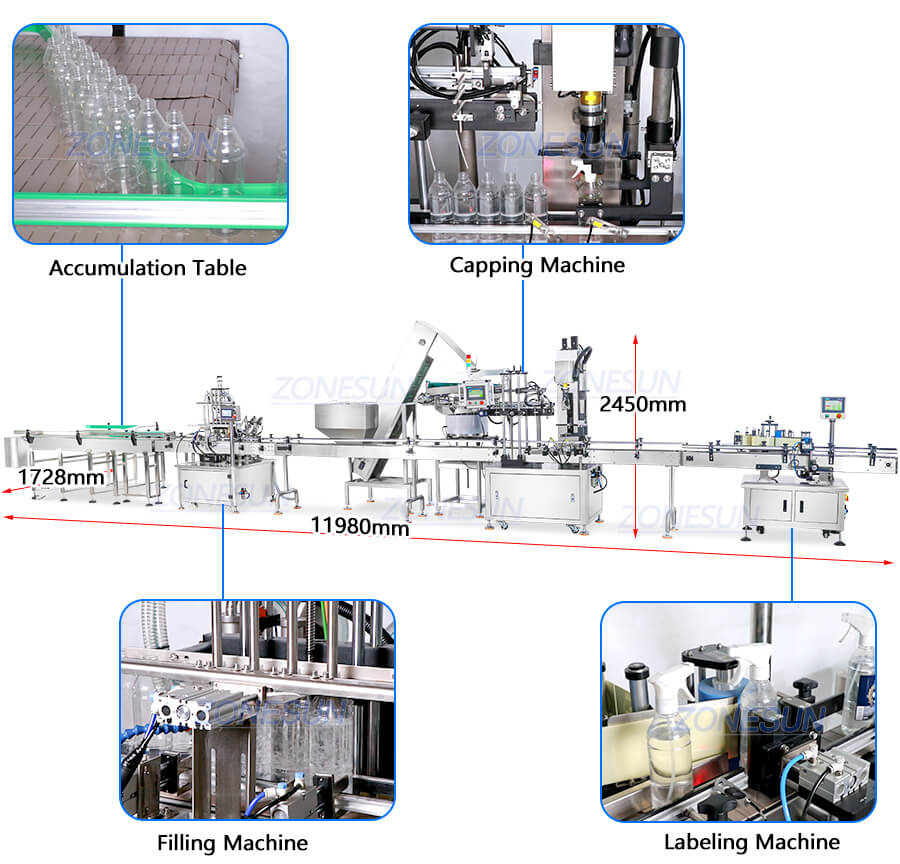

Trigger Pump Spray Bottles Liquid Filling Line

Product Description:

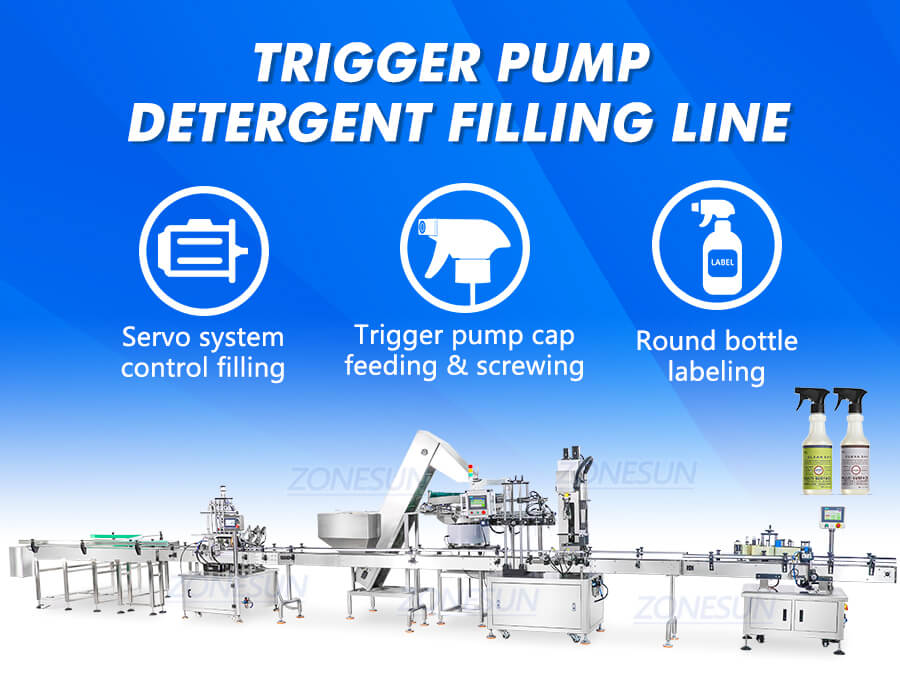

This filling system is specifically designed for liquid bottling, tightening trigger pump bottles, and labeling round bottles. It’s ideal for small to medium-scale detergent production. We can provide customized packaging solutions based on your production needs.

Product Parameters:

| Machine mode | ZS-CB190 |

| Machine power | 1.5KW |

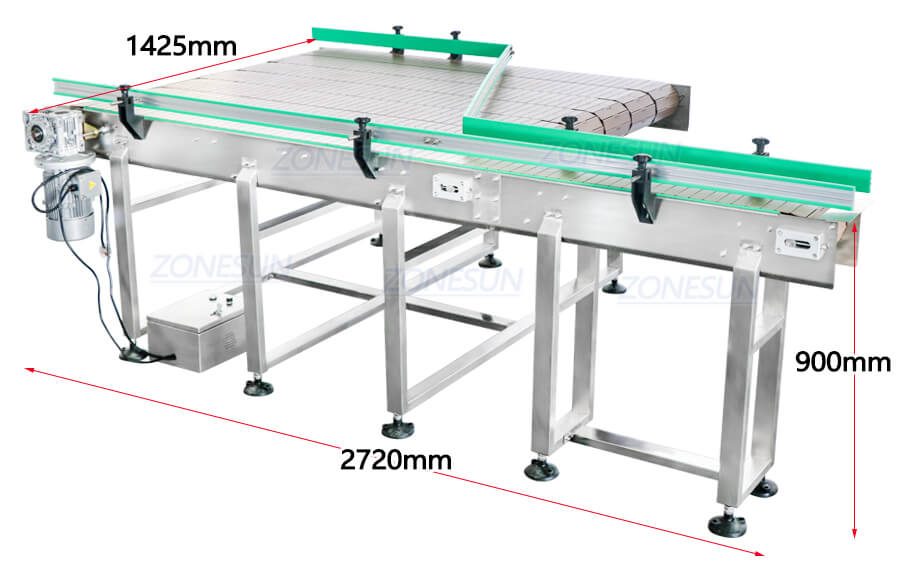

| Conveyor size | 1760*1425mm+960*190.5mm |

| Conveyor width | 190.5mm(Single) |

| Working speed | 0-20m/min |

| Package size | About 2050*1720*720mm |

| Package weight | About 276kg |

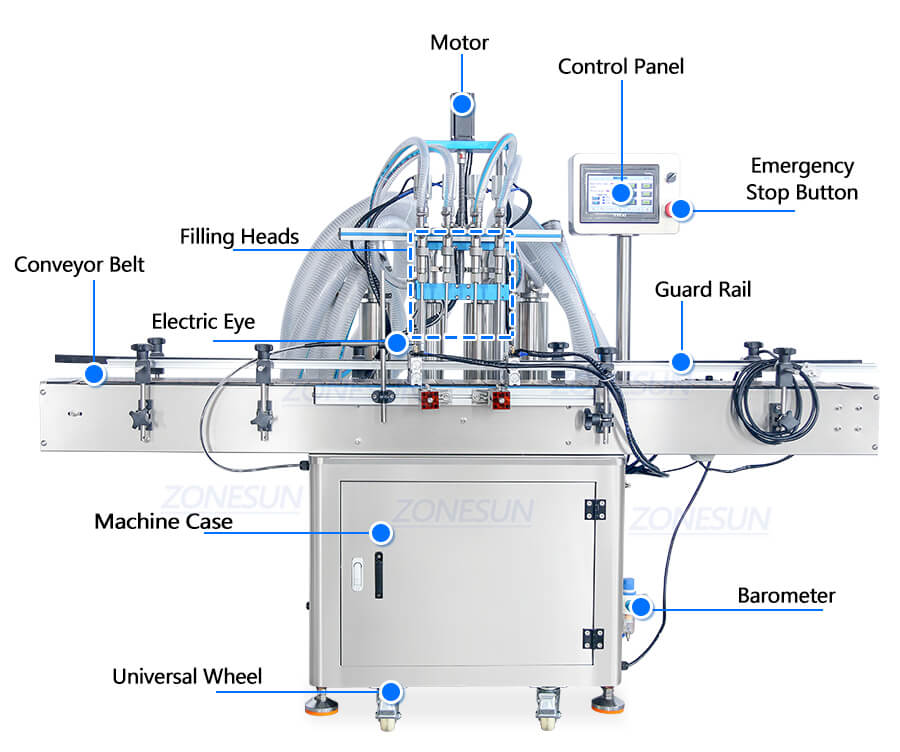

| Machine model | ZS-SV4HS |

| Voltage | 220V/110V 50-60Hz |

| Power | About 6kW |

| Filling range | 100-1000ml(Can be customized) |

| Filling nozzle quantity | 4 |

| Filling pump | Piston Pump |

| Filling speed | About 15-30 bottles/min (depending on bottle size and filling material) |

| Filling error | About ±0.5% |

| Air pressure | 0.5-0.8Mpa |

| Conveyor belt size | About 114*2000mm(W*L) |

| Machine weight | About 130kg |

| Package size | About 2070*760*1670mm |

| Package weight | About 275kg |

| Filling Machine Configuration | ||

| Name | Origin | Brand |

| Low-voltage electrical appliances | China | Delixi |

| Intermediate relay | France | Schneider |

| Electromagnetic valve | Taiwan,China | AirTac |

| PLC | Japan | Mitsubishi |

| Operation Panel | Taiwan,China | WEINVIEW/TECO |

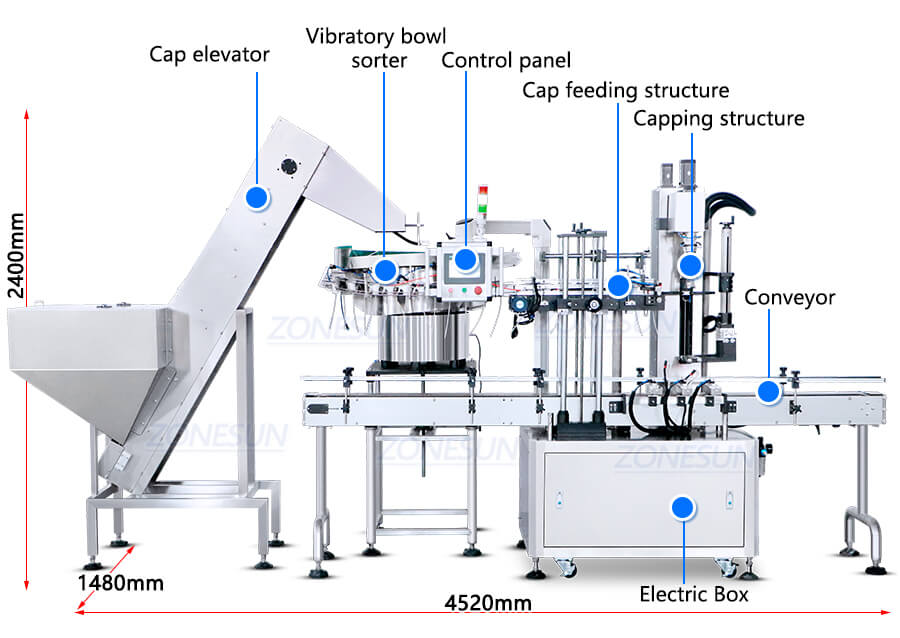

| Machine model | ZS-XG445A |

| Voltage | 110/220V |

| Power | 900W |

| Capacity | 5-23 Bottle/Min(based on bottle and cap size) |

| Material | 304 SUS |

| Air pressure | 0.6-0.8Mpa |

| Suitable bottles | Customize according to sample |

| Cap feeding way | Pneumatic fetch |

| Capping way | Servo drive screw capping |

| Machine size | About4520*1480*2400mm |

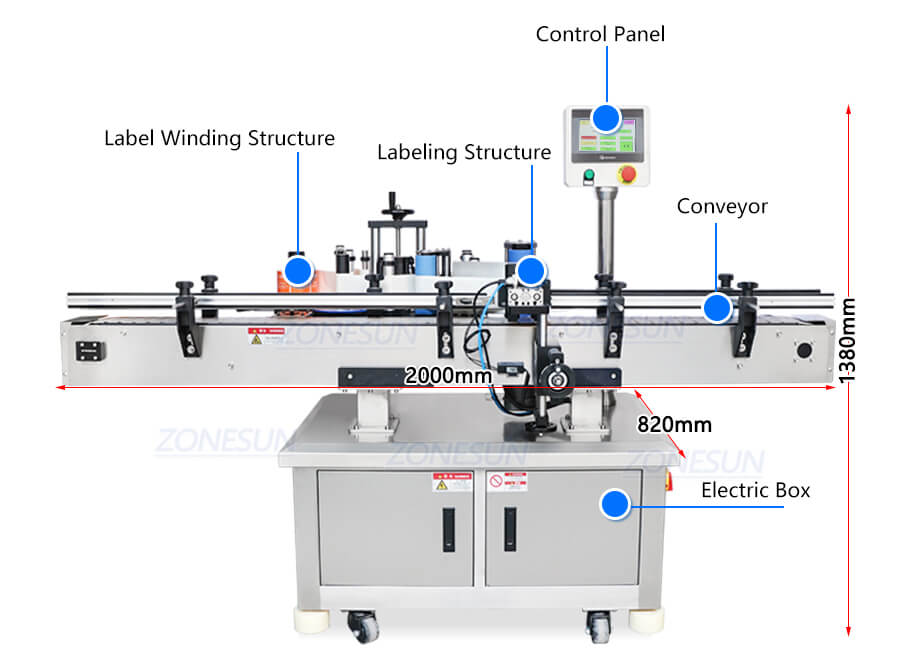

| Model | ZS-TB260R |

| Power supply | AC220V 50Hz/60Hz 1000W |

| Labeling capacity(bottles/min) | 25-50 bottles/min(depends on bottle size) |

| Labeling accuracy(mm) | ±1.0mm |

| Suitable Bottle Diameter | Φ12-100mm |

| Label size(mm) | (L)20-300mm (H)15-150mm |

| Roll inside diameter(mm) | Φ76mm |

| Roll outside diameter(mm) | Φ350mm |

| Conveyor Size | 112*2000mm(W) |

| Machine size | About (L)2000*(W)820*(H)1380(mm) |

| Machine weight | About 180kg |

| Packing Size | About (L)2100*(W)890*(H)1520(mm) |

| Package weight | About 250kg |

Product Details:

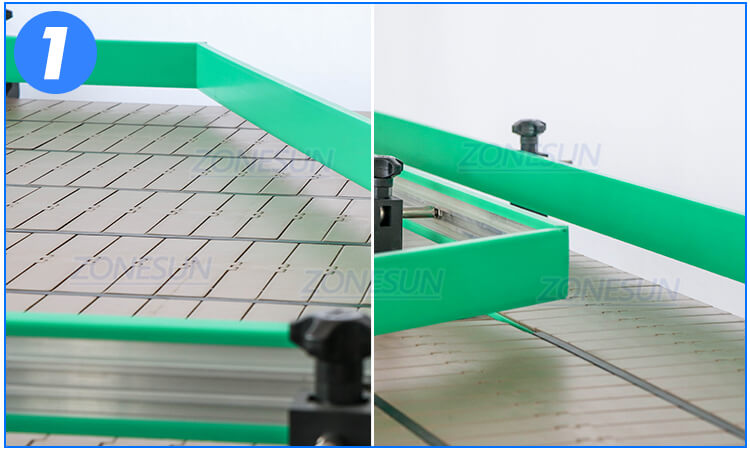

Accumulation Table

This ensures that upstream processes can continue running smoothly.

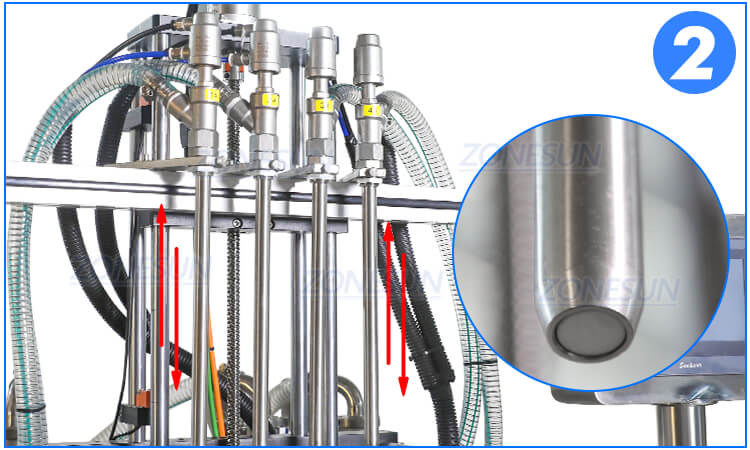

Anti-dripping Diving Nozzle

Good for foamy liquid and can prevent liquid from spraying out during filling.

Servo Piston Pump

Makes machine operation more conveniently and improves filling accuracy.

Cap Feeding & Screwing Structure

Imitating human hands to place cap, the servo capping machine controls the capping to improve the working accuracy.

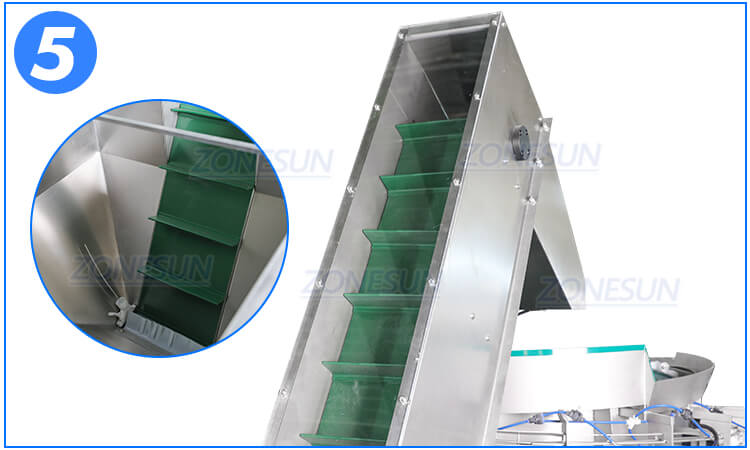

Cap Elevator Machine

Customized according to cap size, it can supply trigger pump caps in time and save working labor.

Vibratory Bowl Sorter

Make caps be in order before capping work and transport them to cap feeding structure.

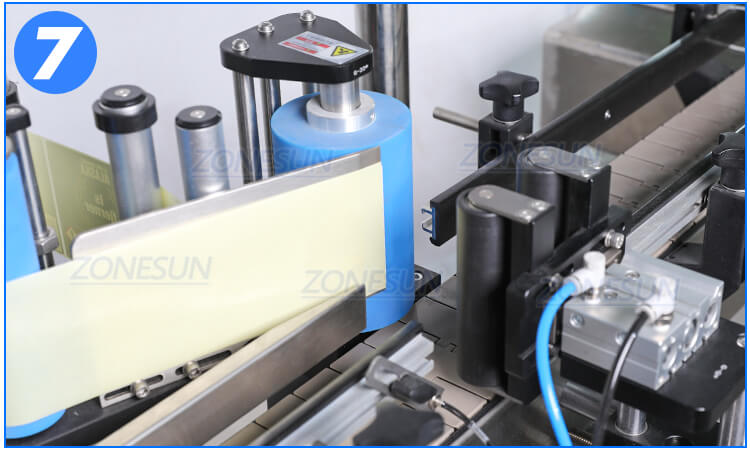

Labeling Structure

Good for sticking labels on round bottles, single/double sides and wrap-around labeling are available.