Test Tube Monoblock Filling Capping Machine

Product Description:

This monoblock machine control work through cam system, it can reach 30BPM, and designed for small volume like liquid solvent.Compact machine body can integrate with bottle labeler to realize automated production.

Product Parameters:

| Machine Model | ZS-AFC36 |

| Voltage | 110/220V 50-60HZ 2KW |

| Filling Range | 0.2-200ml |

| Filling Pump | Ceramic Pump |

| Working Capacity | 20-35BPM(Based On Filling Range) |

| Suitable Bottle Size | φ=10mm*H=45mm (Customizable) |

| Suitable Cap Size | 12-30mm(Customizable) |

| Filling Accuracy | ±0.5% |

| Air Pressure | 0.5-0.7Mpa/cm² |

| Machine Material | SUS304 |

| Machine Size | About 1750*1400*1800mm / 68.9*55.12 * 70.87inch(L*W*H) |

Product Details:

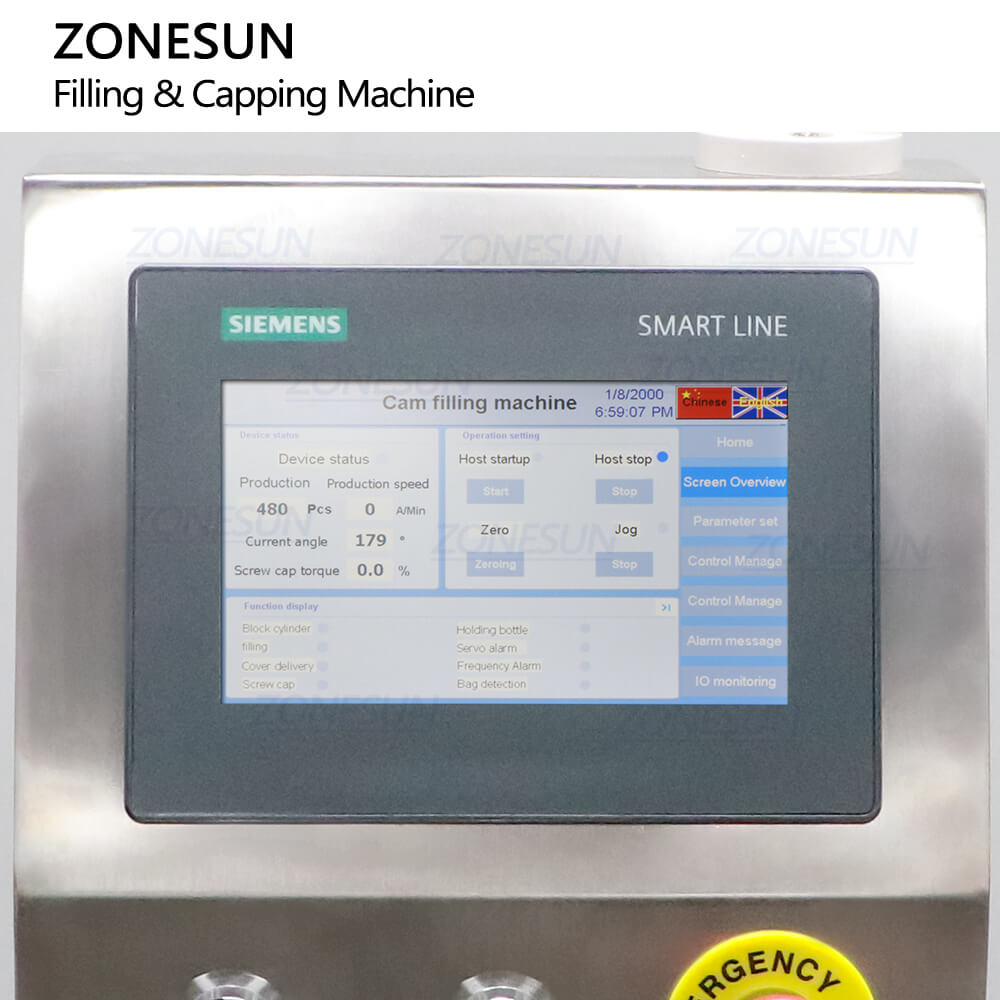

Control Panel

Touch screen control panel makes parameter setting more intuitively, operation language is customizable.

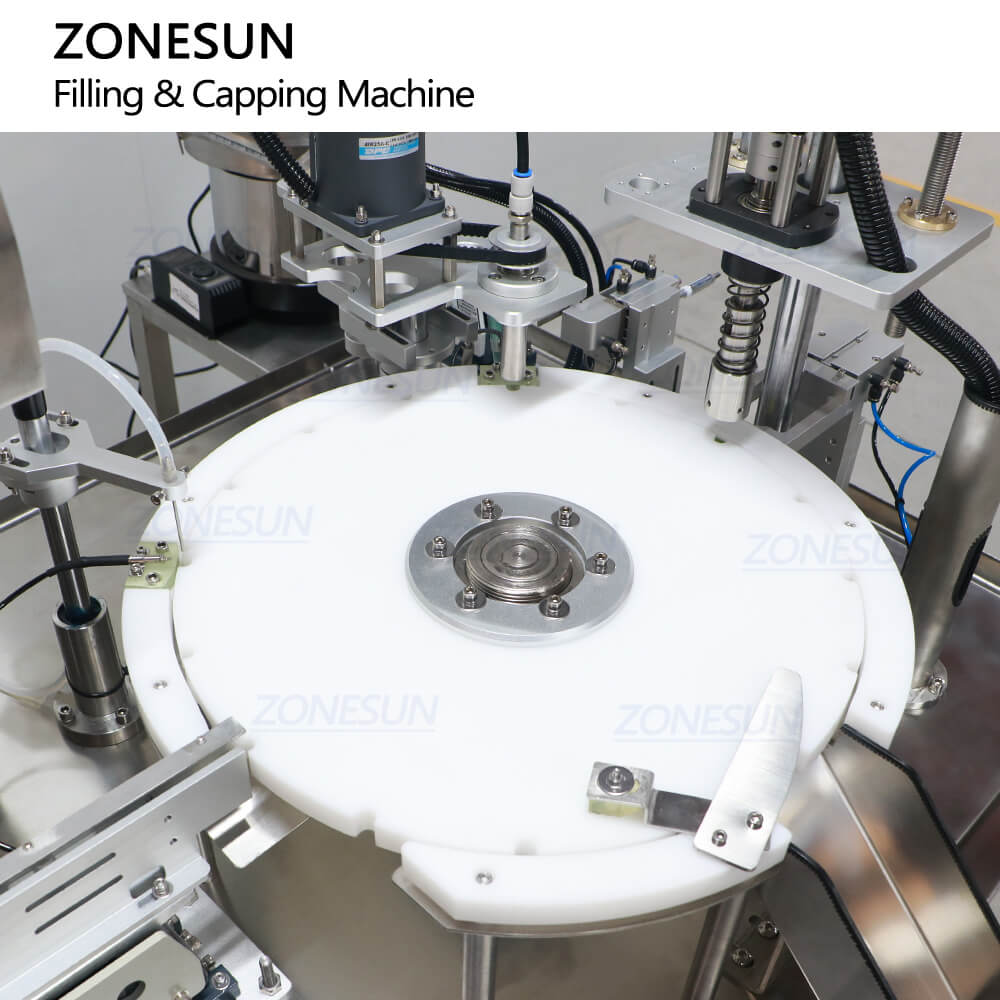

Working Structure

Cam system controls filling, capping work at the same time, it can reach 30BPM, high working capacity.

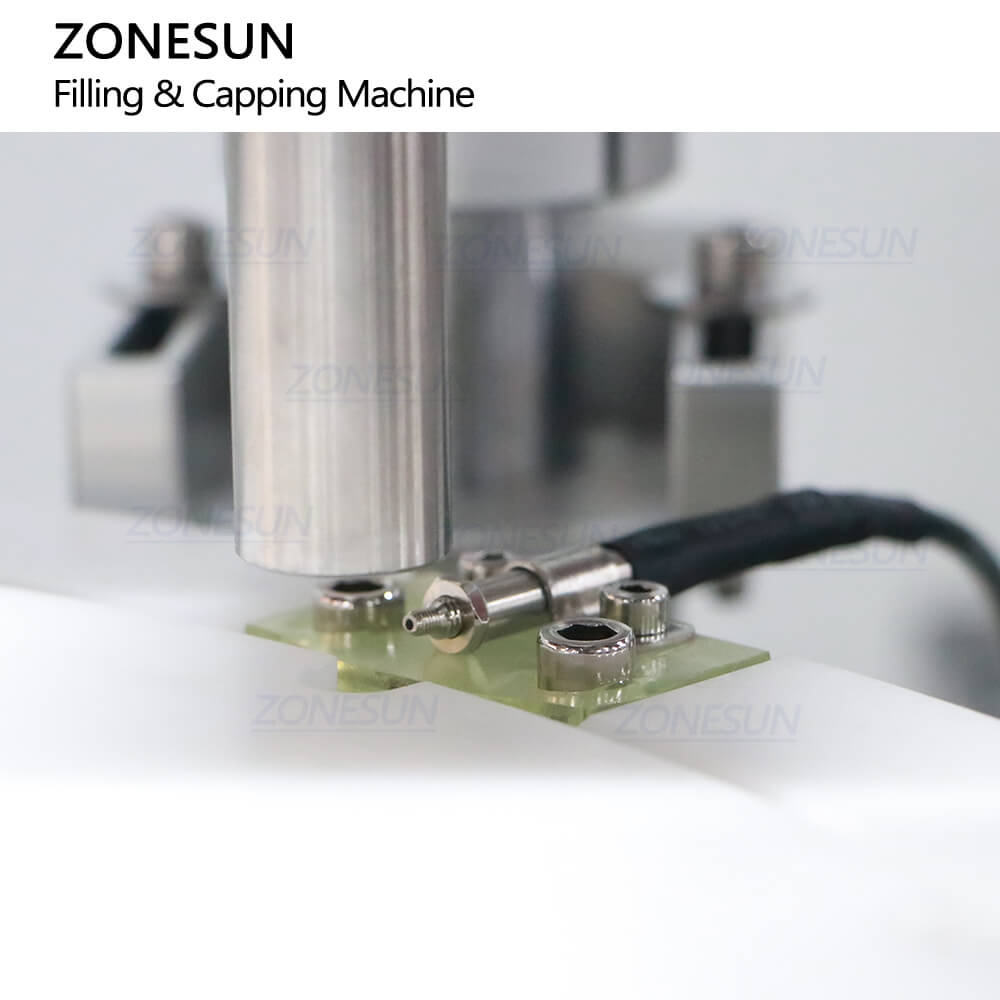

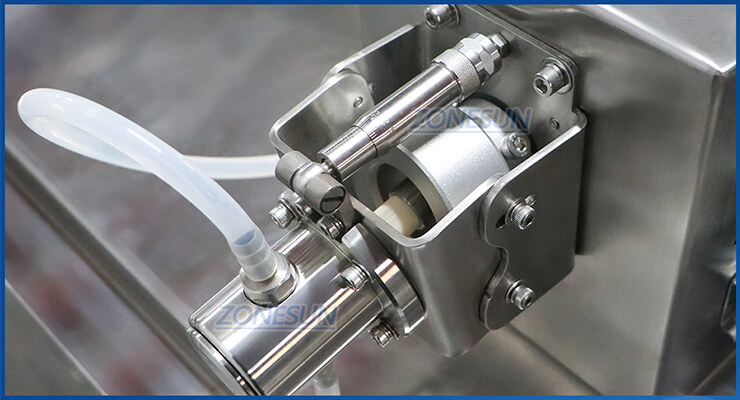

Ceramic Pump

Suits for small filling volume, it has high filling accuracy.

Filling Nozzle

Nozzle size is customizable based on containers’ size. Multi filling nozzles are customizable.

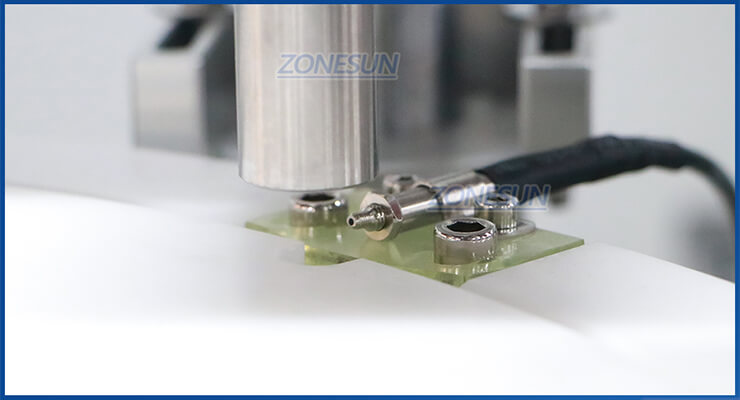

Electric Eye

It detect passing by bottles and control machine to work automatically.

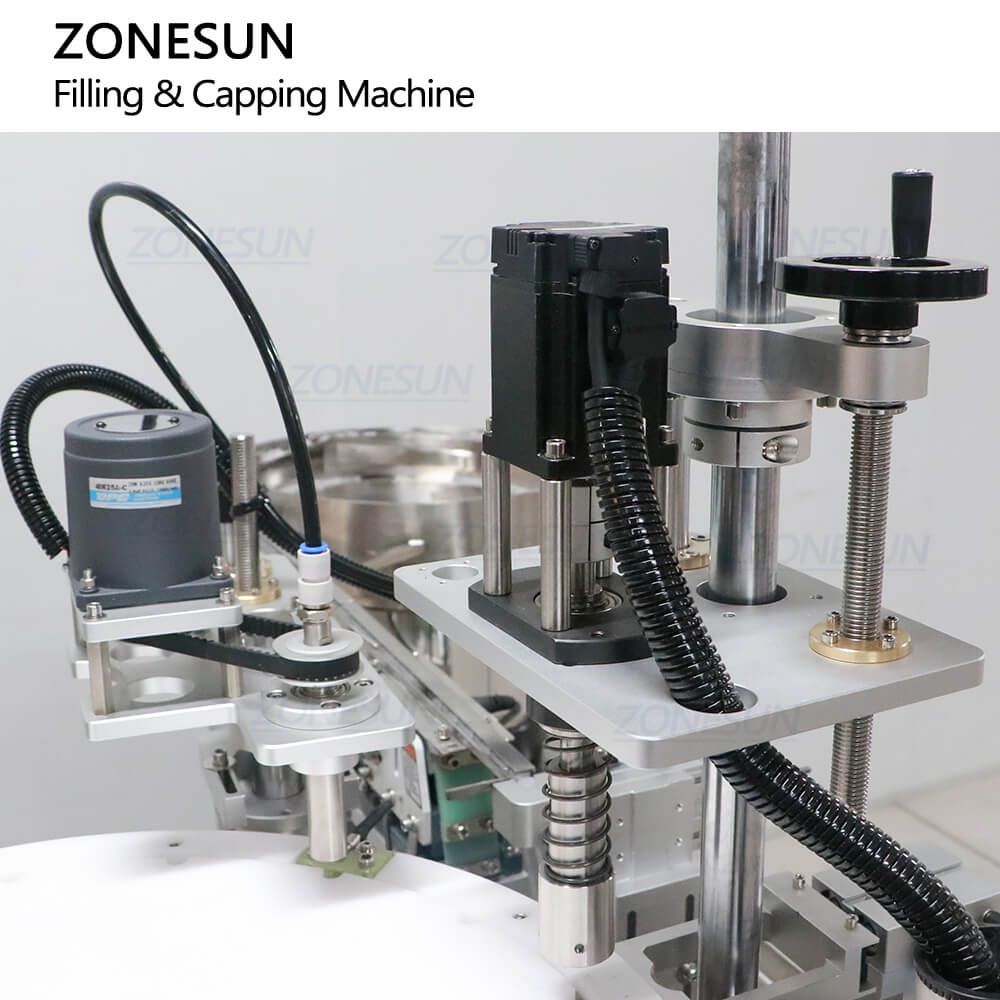

Capping Structure

Controlled by servo motor, capping torsion can be adjusted as production need.

Vibratory Bowl Sorter

These are customizable based on tube and caps size, it can feed tubes and caps to working structure in time.