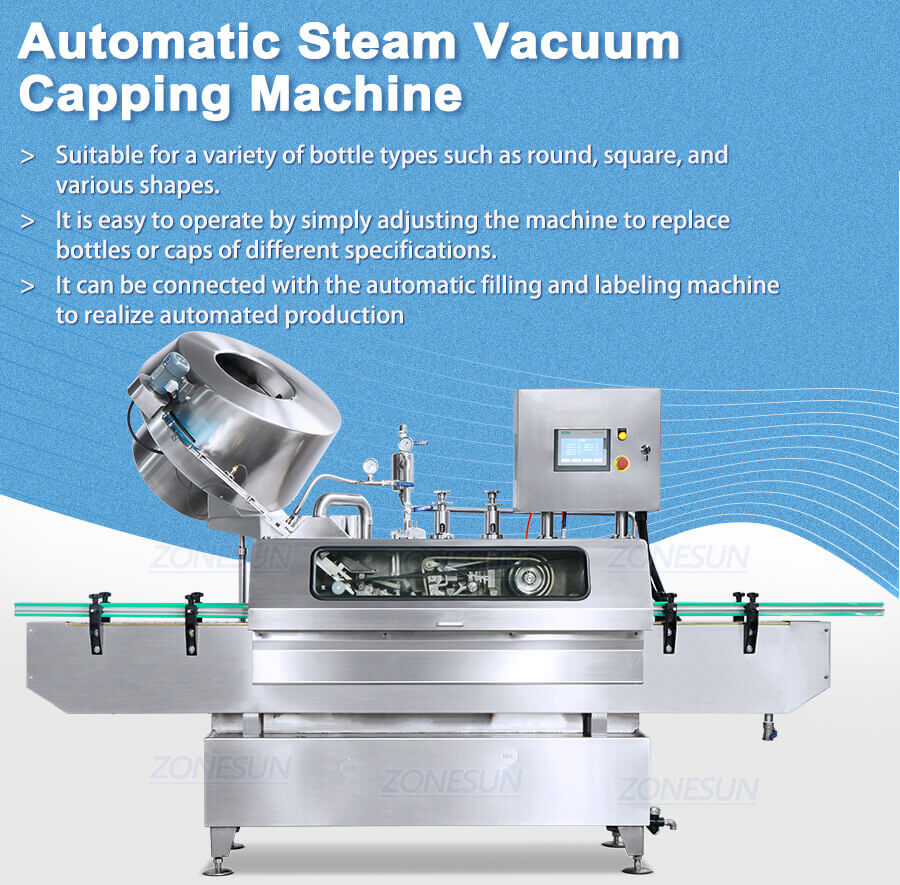

Steam Vacuum Capping Machine

Beskrivelse:

The steam vacuum capping machine is primarily utilized in the bottling and canning industry to ensure a proper and hermetic seal on containers. It injects steam into the headspace (the small space between the product and the container's top), causing the air in the headspace to expand and be forced out of the container. This machine is widely adopted in the food and beverage industries.

Parameter:

| som kan bidra til å mate materiale automatisk. Hjelper deg med å spare produksjonsarbeid og tid. Denne maskinen er egnet for pulverkaker | ZS-XG01 |

| Strømforsyning | 220V/380V 3.12KW |

| Working capacity | About 4000BPH |

| Suitable cap size | Tilpasset |

| Suitable bottle size | Tilpasset |

| Steam consumption | 180-230kg/h |

| Steam pressure | ≤0.4MPa |

| Maximum vacuum degree | 34-67KPa |

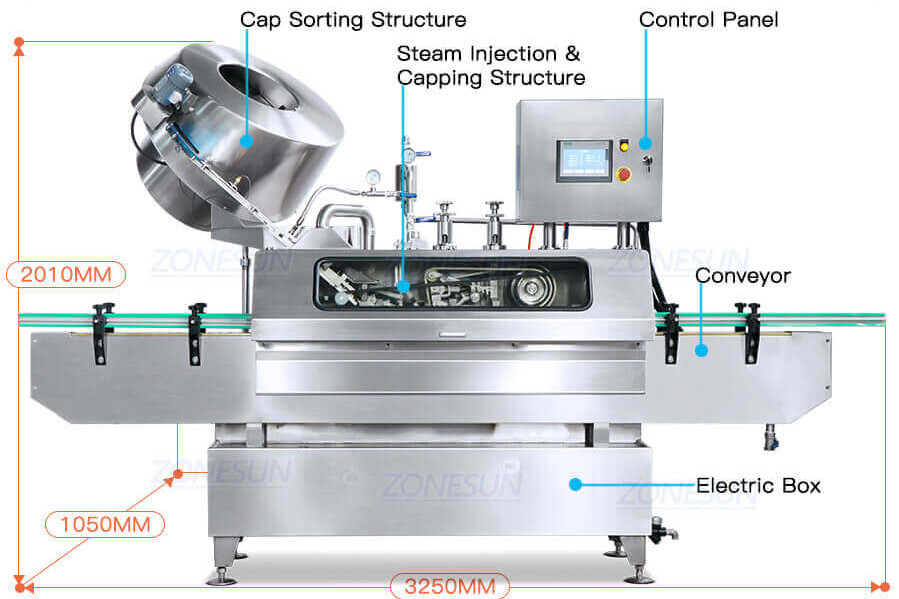

| Maskinstørrelse | About 3250*1050*2010mm |

| Maskinvekt | About 500kg |

Produkt detalj:

The machine comes equipped with a PLC touch screen control panel, providing an intuitive interface for monitoring machine operations. Additionally, it includes an emergency stop button for ensured safety during operation.

The electric rotation cover sorting method is adopted,the working noise is lower,and the cover sorting is smoother, which can greatly improve the working efficiency of the machine.

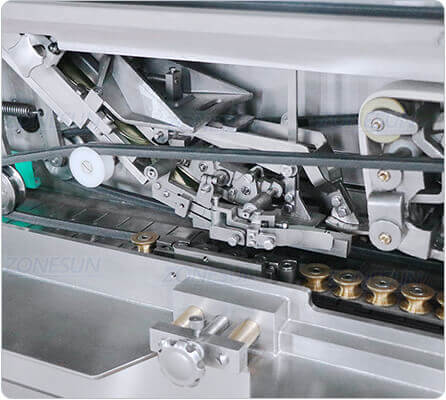

The electric eye can detect metal twist off caps and facilitate automated cap feeding. The guide rail can be adjusted according to cap size, eliminating the need for extra machine components. This is more convenient and expands the application range of the machine.

Before the cap is applied, the bottle first passes through a steam injection area where high-speed steam replaces the normal air in the top space. Following this, the cap is secured by two flat belts, completing the sealing process. This method ensures both product capacity and packaging quality.

The machine in question can be operated with a steam generator, which would require a separate purchase. However, if your product doesn't require vacuum processing, the machine can still function independently without a steam generator for the capping feature.