Automata előre elkészített tasakpaszta kitöltő tömítőgép

termékleírás:

A premade pouch filling and sealing machine is a versatile packaging solution used across various industries. It automates the process of filling and sealing pre-formed pouches or bags, ideal for thick liquids or pastes like yogurt, mosószer, gyümölcslé, and cleaners. The machine is equipped with double filling heads and a powerful piston pump for enhanced performance.

Termékparaméterek:

Gépmodell | ZS-AFS03 |

Feszültség | 380V/220V/110V |

Erő | 3500W |

Production Speed | About 25-45pcs/min(depending on pouch size and filling materials) |

Töltési tartomány | 200-1000ml(Testreszabható) |

Töltő szivattyú | Piston Pump |

Filling Nozzles | 2 Fúvókák |

Sealing Temperature | 100-190℃ |

Premade Pouch Size | (W)80-210mm*(L)100-320mm |

Gépméret | About 2600*1450*1950mm(L * W * H) |

Csomag mérete | About 2480*1460*1680mm(L * W * H) |

Bruttó súly | About 1005kg |

Gép konfigurációja | ||

Machine Component | Márka | Eredet |

Electromagnetic Valve | AirTac | Tajvan,Kína |

Air Cylinder | AirTac | Tajvan,Kína |

Touchscreen | SIEMENS/WEINVIEW | Germany/Taiwan, Kína |

Inverter | Delta | Tajvan,Kína |

PLC | SIEMENS | Németország |

Intermediate Relay | AirTac | Tajvan,Kína |

Temperature Control Panel | YATAI | Shanghai,Kína |

termék leírás:

The PLC operation panel is designed for easy setting and adjustment of working parameters. We can customize the language of the panel to meet your specific needs.

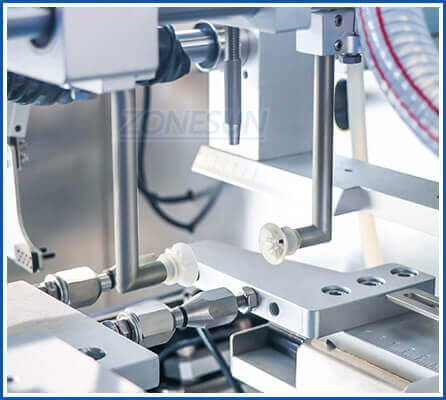

The suction cups are specifically designed for opening pre-made pouches before filling, thereby aiding in labor-saving and enhancing efficiency.

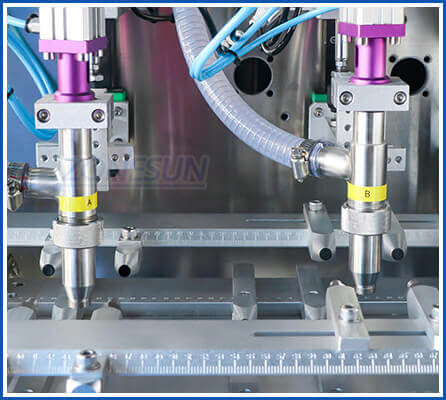

This machine is equipped with pneumatic filling nozzles, allowing it to accurately fill thicker liquids or pastes like laundry detergent and shampoo. It's driven by a piston pump and the number of nozzles can be customized.

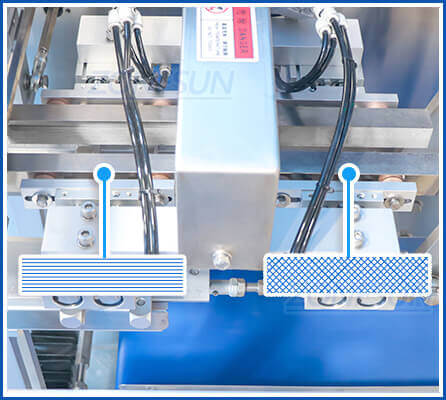

We offer two sealing structures with distinct patterns, selectable based on production requirements. The sealing temperature can be adjusted as needed and is user-friendly.

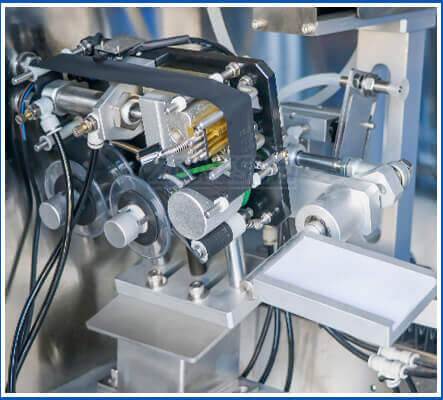

The use of a date coder can automatically print the production date or batch number on the pouch, thereby reducing labor costs.