Trigger Pump Spray Caps Feeding Machine

Product Description:

Some trigger pump spray caps may be long and hard, making it difficult to insert them accurately into the bottle. This cap feeding machine imitates human hands to pick up caps and place them precisely into bottles, with a speed of 23 bottles per minute. It can be connected to filling, capping, and labeling machines for a complete packaging production workflow.

Product Parameters:

| Machine model | ZS-XG445S |

| Voltage | 110V/220V |

| Power | 1.5KW |

| Capacity | 5-25 Bottle/Min(based on bottle and cap size) |

| Air pressure | 0.5-0.8Mpa |

| Suitable bottles | Customize according to sample |

| Cap feeding way | Pneumatic fetch |

| Machine size | About 3000*1300*2100mm(L*W*H) |

| Packaging size | About 1090*640*1960mm(machine) About 1060*970*1570mm(Vibratory bowl sorter) |

| Packaging weight | About 210kg(machine) About 106kg(Vibratory bowl sorter) |

Product Details:

The machine is equipped with a touch screen control panel, allowing for easy debugging. We can customize the operation language based on your needs. Additionally, alarm lights are available to indicate various machine states, ensuring timely responses to critical events.

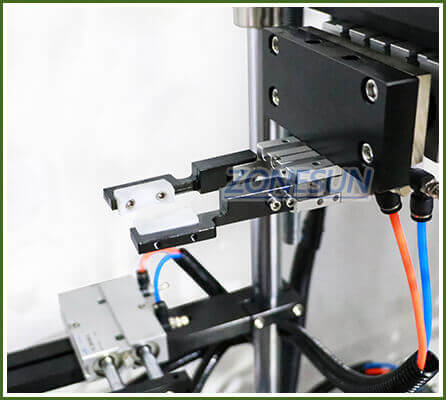

This machine is designed to mimic human hand movements, specifically for picking up caps and securely placing them into bottles. It's ideal for trigger pump sprayers with long and sturdy tubes.

The machine is equipped with a sensor that detects spray cap availability. If the stock runs low, it sends a signal to the system to replenish the caps in a timely manner, enhancing operational efficiency.

Guide housings enhance machine element movement, ensuring smooth and precise operation, thereby boosting performance and productivity.

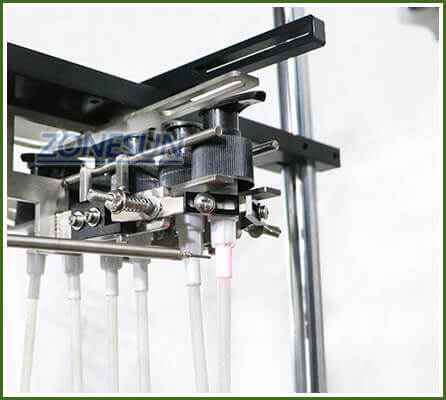

The cylinder regulates the operation of the components, ensuring a seamless cap-taking process. The working height of this component can be adjusted as needed, accommodating different sizes of trigger pump caps.

This model comes with a chain conveyor belt, offering a substantial weight capacity for bottle transportation. The width of the conveyor belt can be tailored to your specific operational requirements.