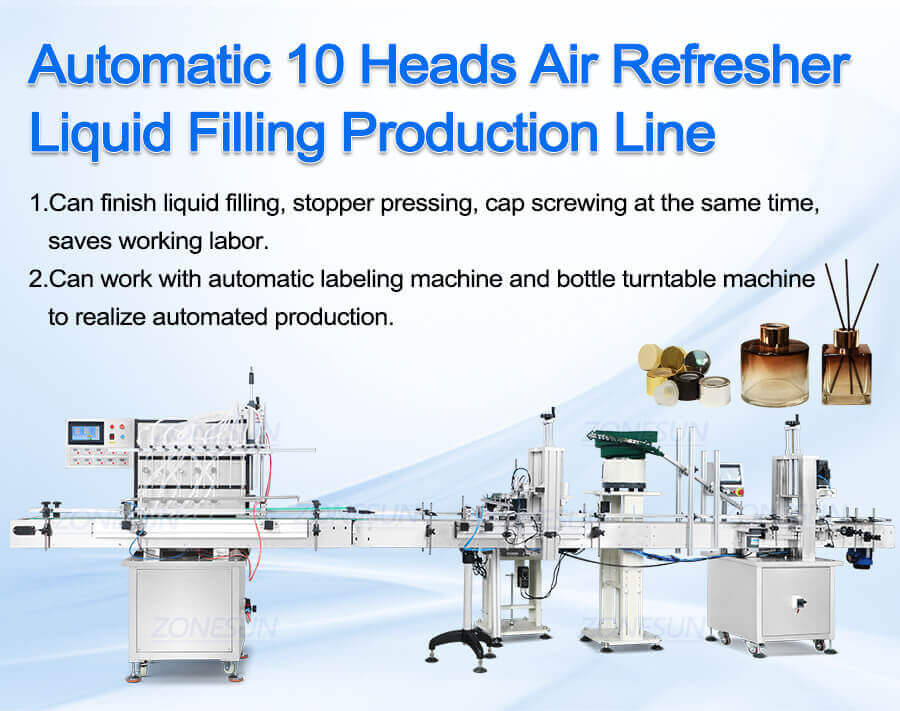

Outomatiese 10 Heads Air Refresher Produksielyn vir vloeistofvul

Produk Beskrywing:

This liquid filling line consists of 10 heads filling machine, stopper pressing, and cap screwing machine. It can simultaneously complete liquid filling, stopper pressing, and cap screwing. It can also be connected to an automatic labeling machine and bottle turntable machine to save labor.

Produk Parameters:

| Masjienmodel | ZS-VTMP80C10 |

| Spanning | 110/220V 50-60hz |

| Filling pump | 316 Stainless steel magnetic pump |

| Max flow rate | 6L/min |

| Working capacity | About 20-40BPM( based on filling material and filling volume) |

| Vul akkuraatheid | ≤±1% ( based on filling material and filling volume) |

| Grootte van lugkompressoraansluiting | OD 8mm |

| Pakkie grootte | About 1960*720*1730mm |

| Package weight | Ongeveer 250 kg |

| Masjienmodel | ZS-XG16X |

| Working voltage | 220V/110V 50- 60HZ |

| Bottel hoogte | 30-300mm |

| Cap diameter | 18-70mm |

| Bottle diameter | 20-160mm |

| Werkspoed | 10-25 bottels/min(depending on cap size and shape) |

| Working pressure | 0.4-0.6MPa |

| Grootte van lugkompressoraansluiting | OD 8mm |

| Pakkie grootte | About 1970*510*990mm(Stopper Pressing Machine)+2020*770*1750mm(Screw Capper) |

| Totale gewig | About 104kg(Stopper Pressing Machine)+303kg(Screw Capper) |

Produk besonderhede:

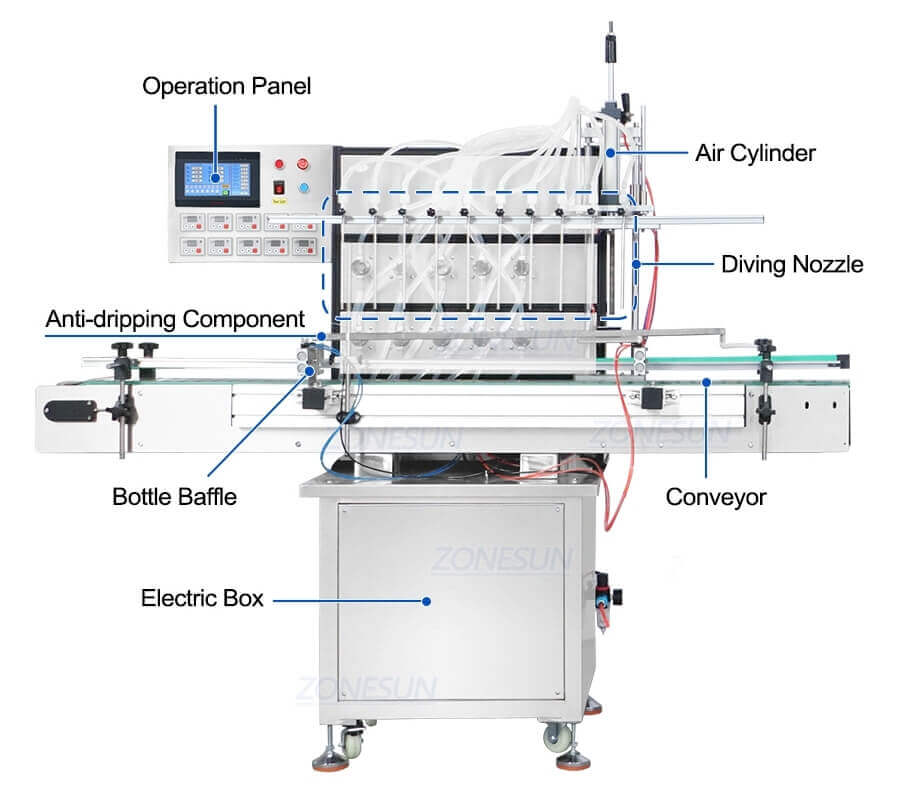

The PLC control panel offers real-time display of working data, providing a more intuitive interface that streamlines machine operation. It can be customized into various languages based on production requirements.

The filling system is equipped with a 316 stainless steel magnetic pump, ensuring high filling accuracy. The diving filling nozzle prevents liquid from splashing during filling, making it ideal for foamy liquids. Customizable multiple filling nozzles are available upon request.

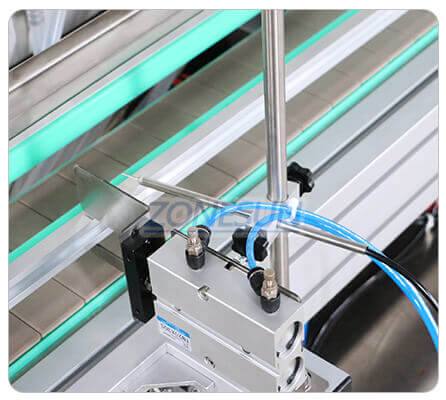

The electric eye system can detect bottles passing by and automatically trigger the filling and capping process, enhancing operational efficiency.

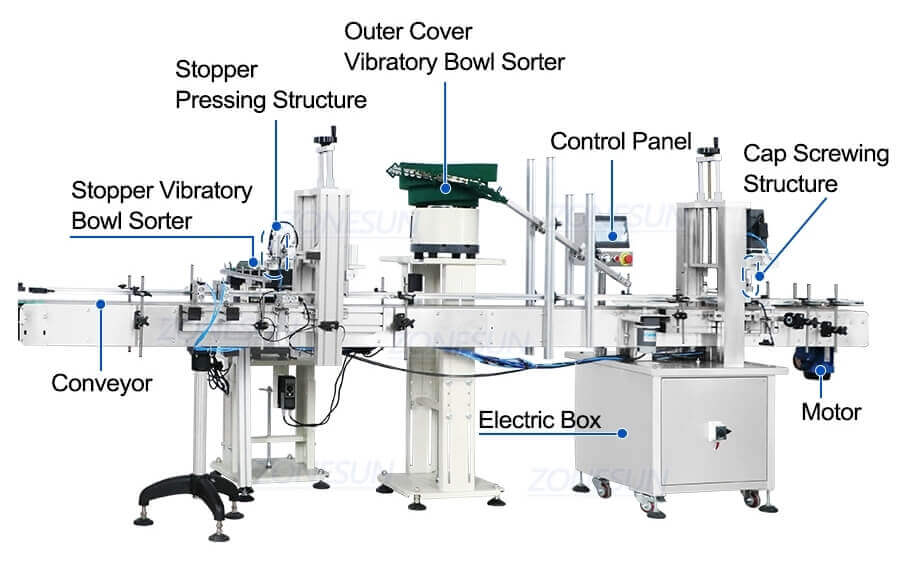

The air nozzles, controlled by an air cylinder, can pass through stoppers and place them on the bottle mouth like a human hand. This is ideal for light caps or stoppers and provides high working accuracy.

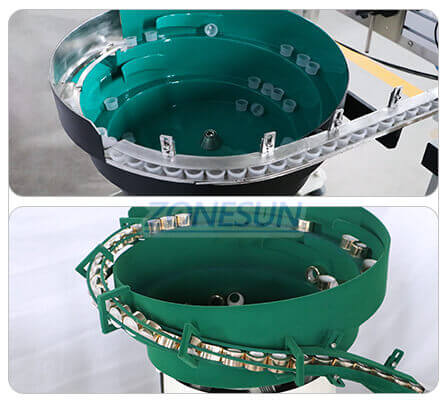

Vibratory bowl sorting machines streamline the sorting process, reducing manual labor and boosting efficiency. They are tailored to specific sizes and offer high accuracy.

The capping structure can be adjusted for different bottle cap sizes and shapes, making it suitable for various types of caps, including spark caps, dropper bottles, and sharp-pointed bottles.

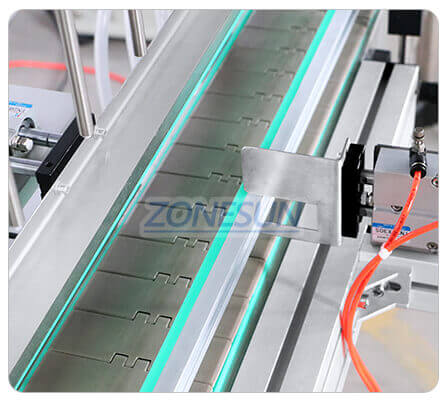

The chain conveyor can be tailored to your specific production requirements, ensuring it has a larger weight capacity and delivers products more stably and smoothly.