Vial Filling Stoppering Machine

Produst Description:

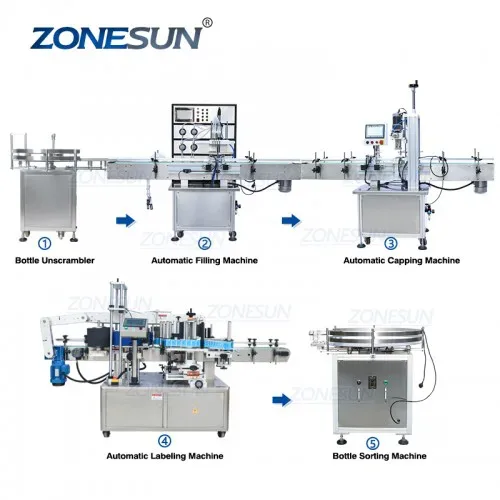

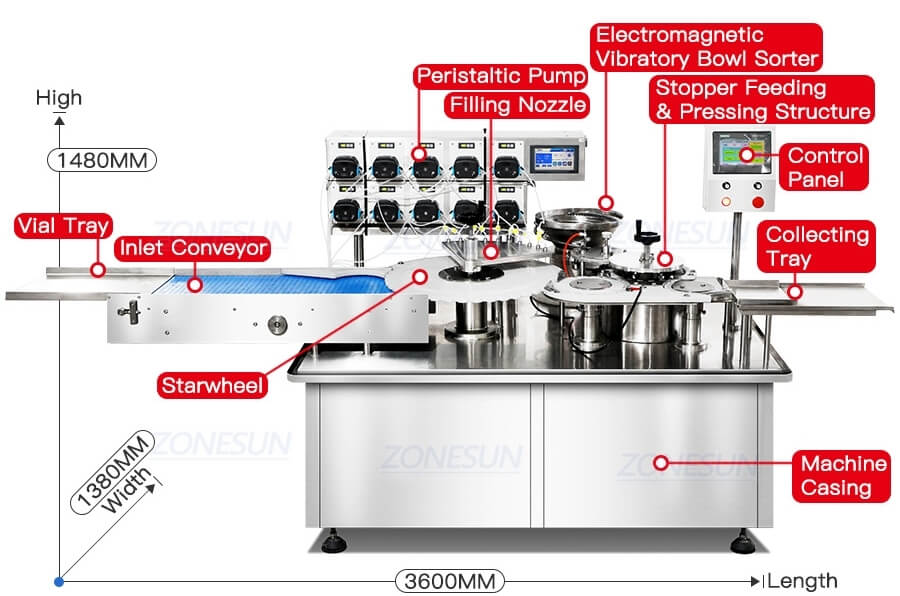

This monoblock vial filling stoppering machine is designed for small-to-medium scale production. It integrates bottle unscrambling, liquid filling (via peristaltic pump), stopper sorting/insertion, pressing, and vial collection into a single compact unit. Precise bottle positioning is ensured by a star wheel transport mechanism, maintaining accuracy throughout the process. Ideal for seamless integration with vial crimping machines to achieve end-to-end production.

Product Parameters:

| Machine model | ZS-AFY1 |

| Machine voltage | 220V 50HZ 4KW |

| Filling pump | Peristaltic pump |

| Filling range | 2ml (Customizable) |

| Filling accuracy | ±1-2% |

| Working capacity | 12000BPH |

| Suitable bottle size | Customizable |

| Suitable cap size | Customizable |

| Machine size | About 3060*1380*1480mm |

| Package size | About 2390*1420*1620mm |

| Package weight | About 1147kg |

Product Details:

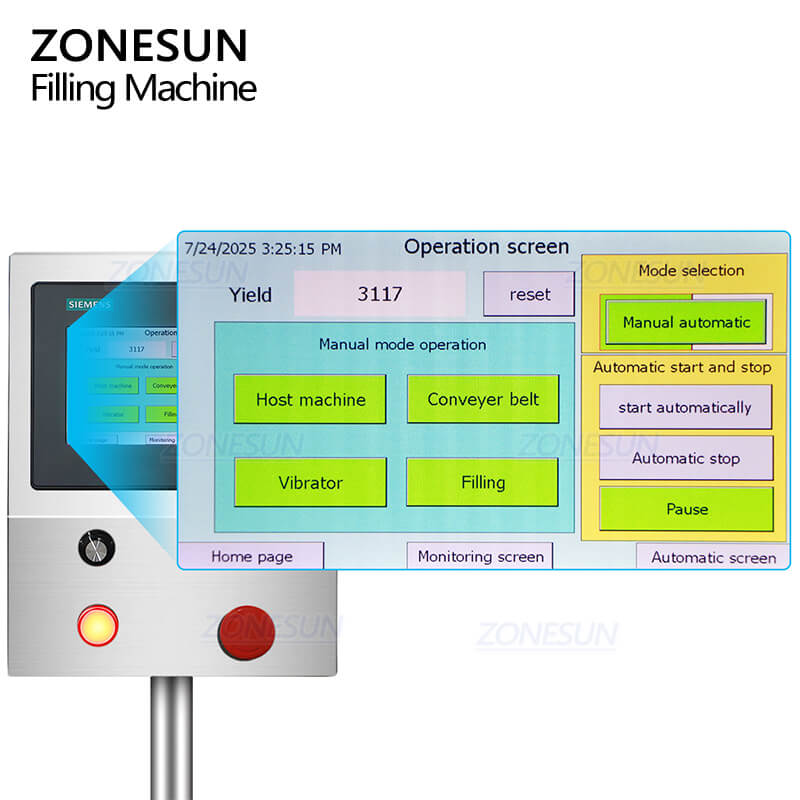

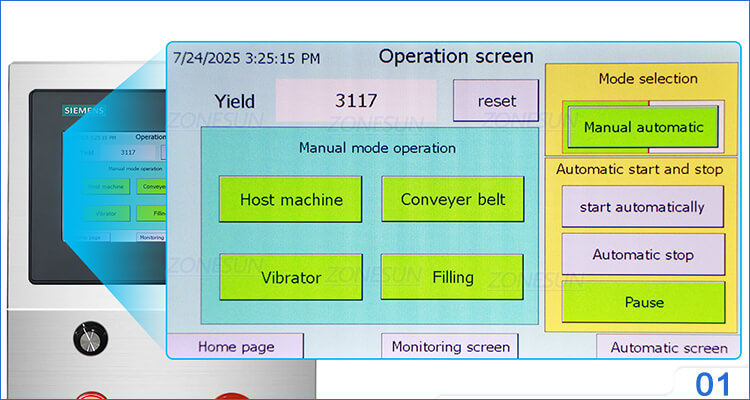

Touchscreen Control Panel

User-friendly interface for intuitive operation, parameter adjustment, and real-time monitoring.

Peristaltic Pump Filling

Ensures high precision and clean dosing, idear for material changeover and avoid cross-contamination.

Electromagnetic Vibrating Bowl

Provides stable and low-noise feeding of rubber stoppers, improving working environment and accuracy.

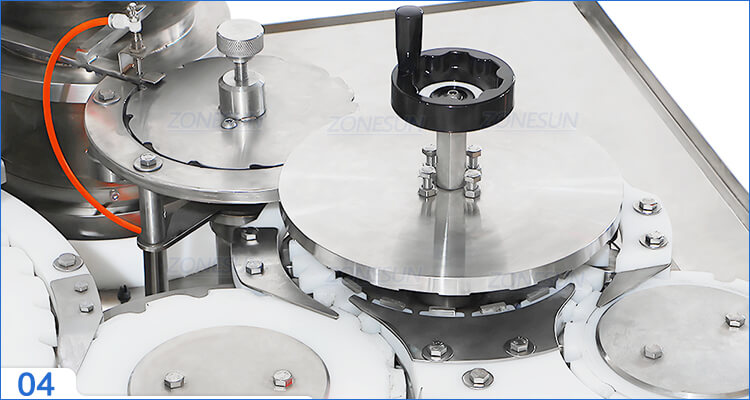

Stopper Inserting & Pressing

Equipped with precise alignment and pressing units, stopper pressing depth is fully adjustable.

Starwheel Transporting

Bottles are conveyed smoothly and accurately via star wheel for synchronized processing across all stations.

Vial Collecting Tray

Finished vials are automatically collected at the discharge area or directed to a capping unit for further processing.