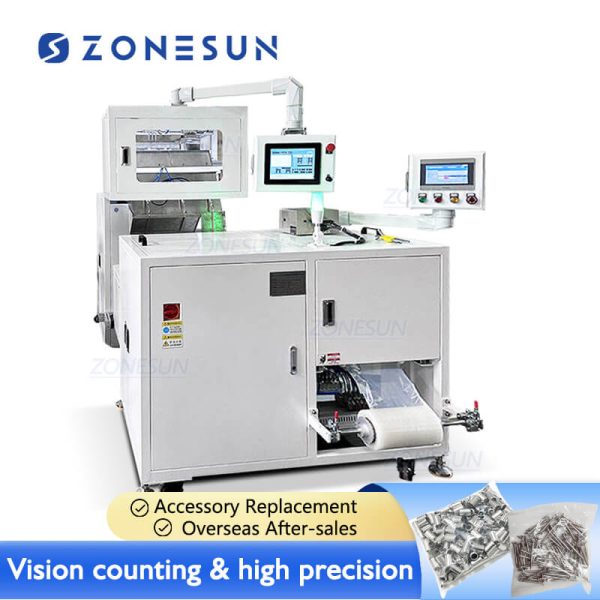

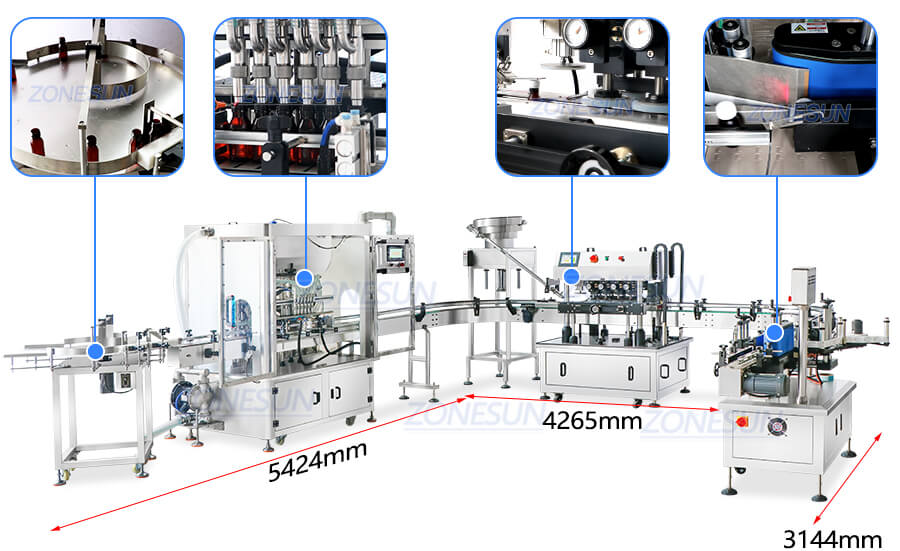

Servo Paste Filling Capping And Labeling Machine

Product Description:

This production line consists of a bottle turntable machine, a servo system piston pump filler, a high-speed bottle capper, and a bottle labeling machine. It’s ideal for small to medium-scale production of honey, syrup, and similar pastes.

Product Parameters:

|

Machine Model

|

ZS-LP800N

|

|

Power Supply

|

220V/110V 50-60Hz 200W

|

|

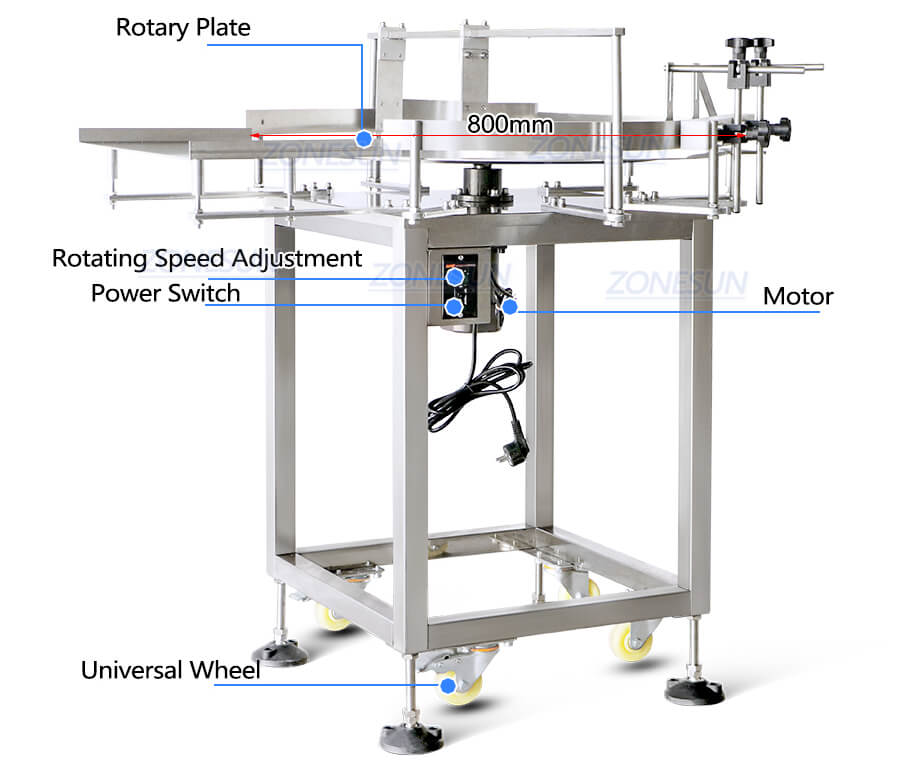

Turntable Diameter

|

800mm

|

|

Suitable Bottle Diameter

|

20-100mm

|

|

Suitable Bottle Height

|

30-320mm

|

|

Working Speed

|

40-60 bottles/min(depending on bottle size)

|

|

Package Size

|

About 1230*1010*1260mm

|

|

Gross Weight

|

About 141kg

|

|

Machine Model

|

ZS-YT6T-6PXD

|

|

Voltage

|

110/220V 50-60HZ

|

|

Power

|

2KW

|

|

Filling Heads

|

6 Heads(Can be customized)

|

|

Filling Range

|

50-500ml(Can be customized)

|

|

Filling Speed

|

About 20-70bottles/min(depending on materials and bottle size)

|

|

Filling Accuracy

|

±1%

|

|

Air Pressure

|

0.5-0.8MPa

|

|

Memory Function

|

Available

|

|

Machine size

|

About 2500*950*1900mm(L*W*H)

|

|

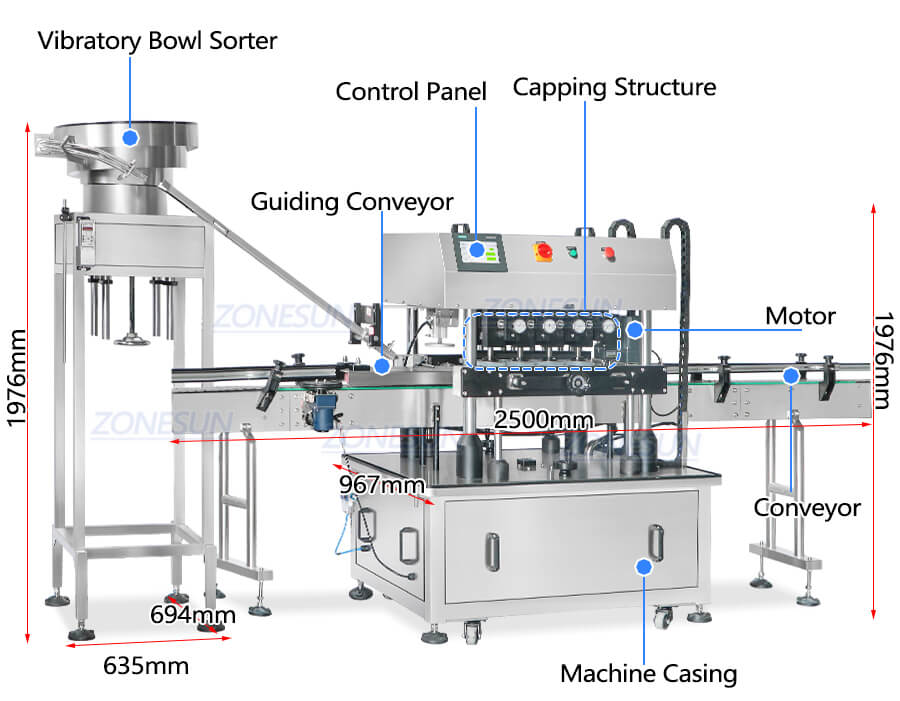

Machine Model

|

ZS-XG440B

|

|

Voltage

|

220V/110V 50-60Hz

|

|

Power

|

2KW

|

|

Production Capacity

|

2000-5000BPH (depending on bottle and cap size)

|

|

Suitable Cap Size

|

Customized

|

|

Suitable Bottle Diameter

|

35-120mm(Can be customized)

|

|

Suitable Bottle Height

|

60-200mm(Can be customized)

|

|

Machine Size

|

About 2500*967*1686mm( Main Machine )

+ About 635*694*1976mm( Vibratory Bowl Sorter)

|

|

Package Size

|

About 2060*1070*1920mm( Main Machine ) +

About 1950*730*720mm( Vibratory Bowl Sorter)

|

|

Machine Weight

|

About 614kg ( Main Machine )+165kg( Vibratory Bowl Sorter)

|

|

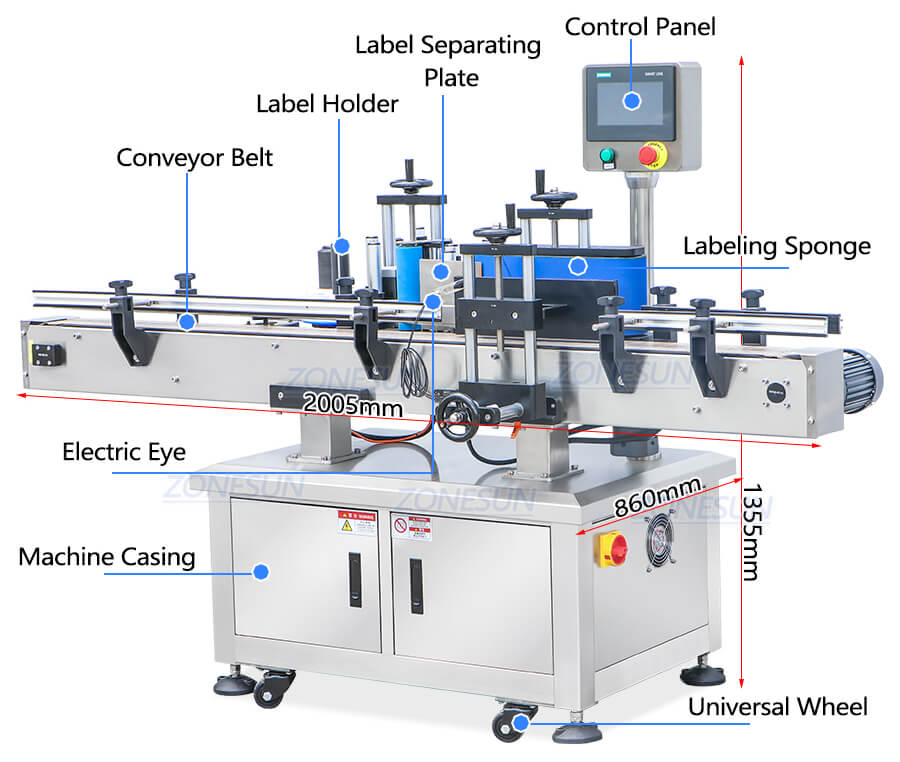

Machine Model

|

ZS-TB200R

|

|

Voltage

|

220V/110V 50-60Hz

|

|

Power

|

1200W

|

|

Labeling Speed

|

About 40-150 bottles/min(depending on bottle and label size)

|

|

Suitable Bottle Diameter

|

30-100mm

|

|

Suitable Bottle Height

|

30-200mm

|

|

Label Size

|

15-130mm(W)*15-300mm(L)

|

|

Label Roll Inner Diameter

|

Φ76mm

|

|

Label Roll Outer Diameter

|

Φ350mm

|

|

Machine Size

|

About 2005*860*1355mm

|

|

Machine Weight

|

About 200kg

|

Product Details:

Support Arm Control Panel

Easier and more intuitively for parameter setting.

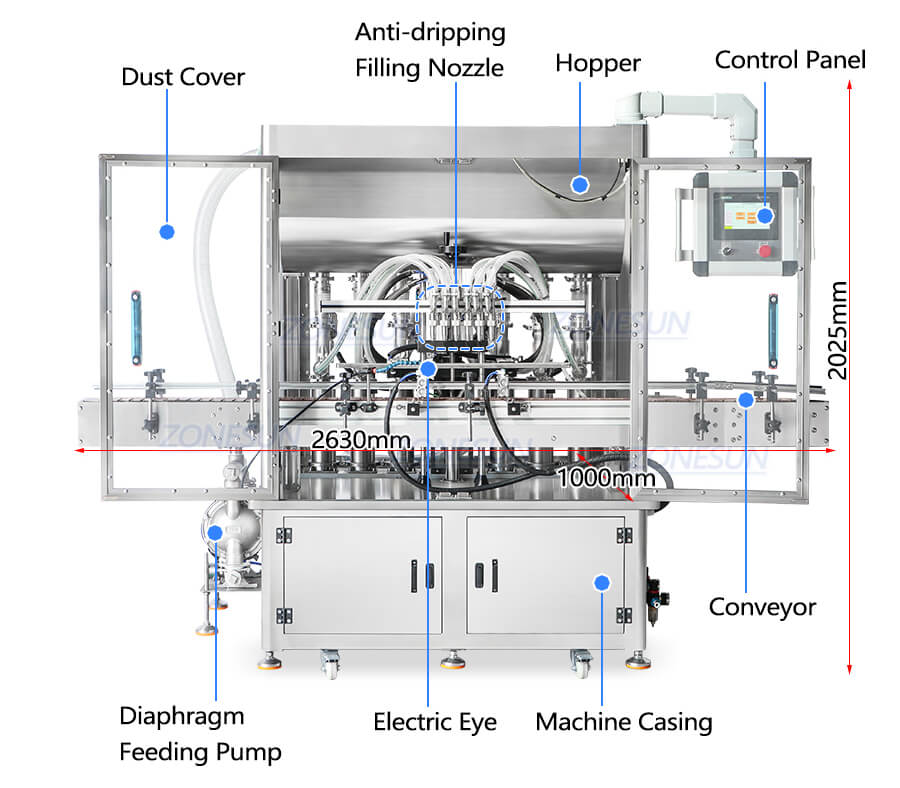

Anti-dripping Filling Nozzles

Prevent sticky paste cling to the nozzle’s outer surface and lead to dripping.

Servo Piston Pump Filling

Set filling volume directly, more accurately.

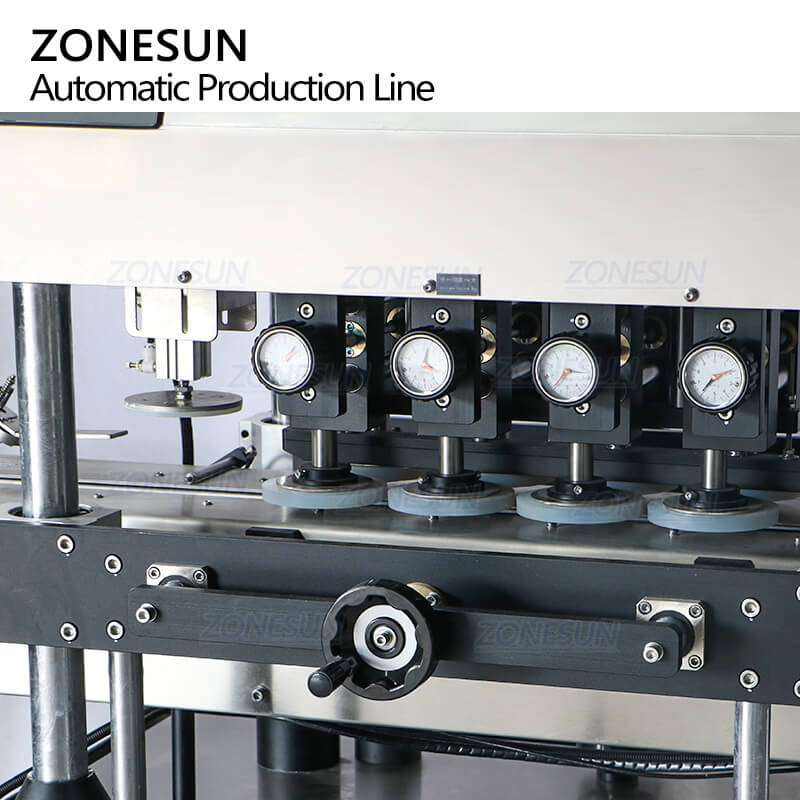

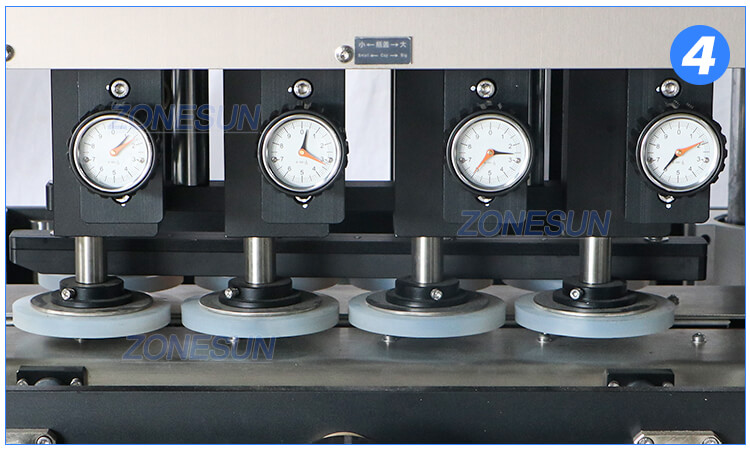

Inline Capping Structure

Can tighten multi bottles with screw thread at the same time.

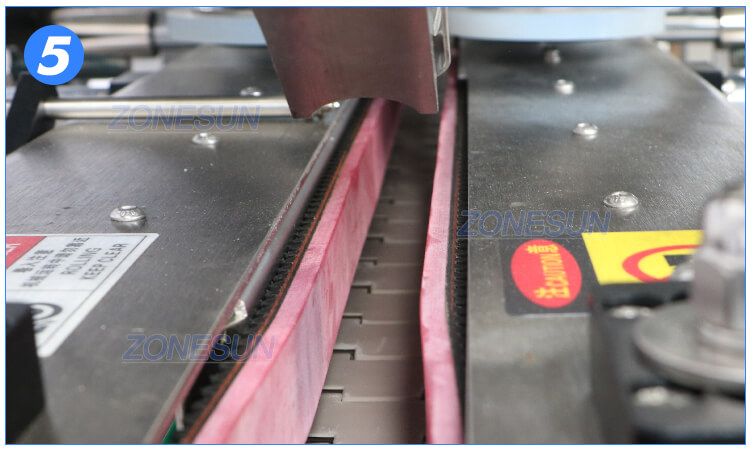

Guiding Conveyor

Clamp bottles and prevent from falling down during conveying.

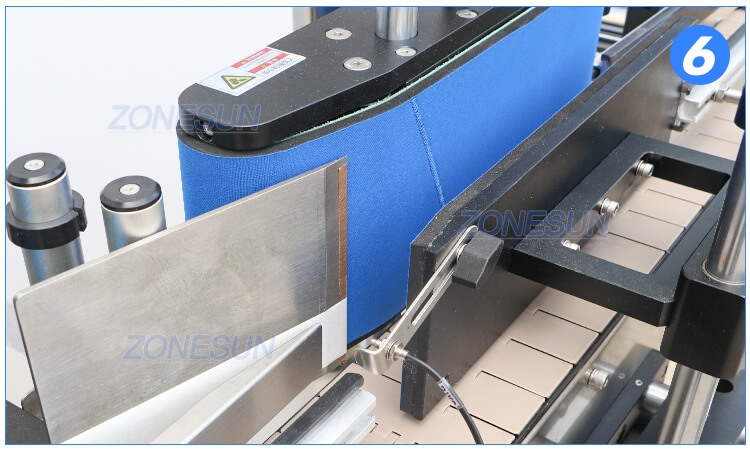

Labeling Structrure

Suitable for single side labeling for round bottles, can reach 40-150BPM (work separately)

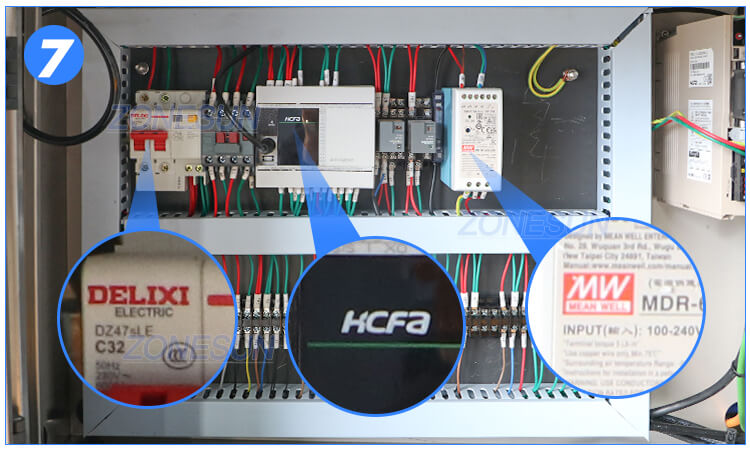

Part Configuration

High quality electrical apparatus element ensure stable working status.