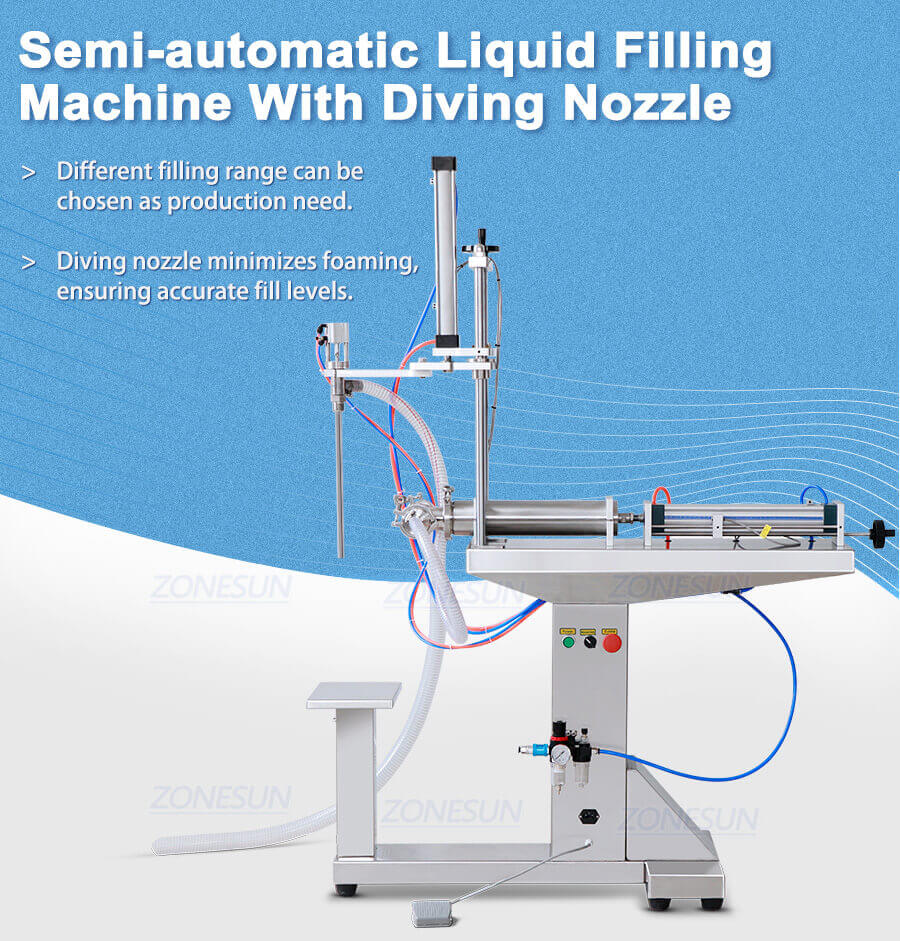

Semi Automatic Liquid Filling Machine With Diving Nozzle

Product Description:

This semi-automatic piston pump filling machine, equipped with a diving nozzle, is ideal for food and cosmetic industries. It accurately draws products from a tank and fills containers, minimizing foaming. Although not fully automated, it's versatile, adjustable, and cost-effective for small to medium-scale production.

Product Parameters:

| Machine Model | ZS-YTFS1D |

| Voltage | 220V/50Hz 110V/60Hz |

| Power | 100W |

| Energy Source | Electric and pneumatic |

| Filling Nozzle | 1 Diving Nozzles |

| Filling Range | 5-100mL /10-300mL / 50-500mL /100-1000mL/500-3000mL / 1000-5000mL |

| Filling Speed | About 6-10 bottles/min |

| Filling Accuracy | +0.5% |

| Air Pressure | 0.4-0.6MPa |

| Height of Bottle Holder | Customized |

| Package Weight | About 1370*460*1020mm |

| Package Size | About 110kg |

Product Details:

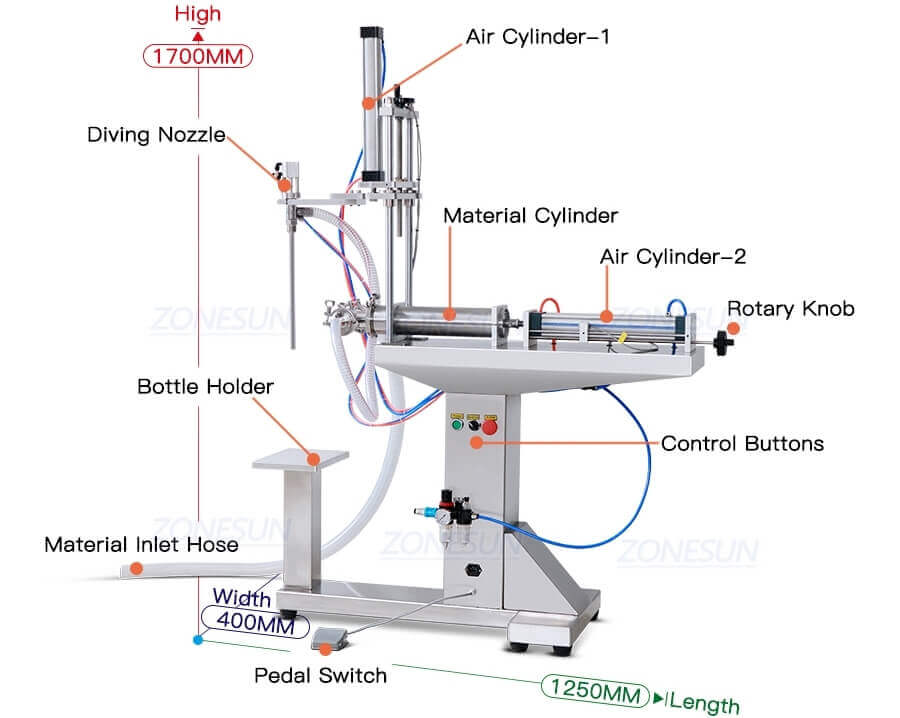

The machine is designed for easy operation with a simple control button. Additionally, it can be controlled via a pedal switch, freeing up your hands for handling containers and other tasks during the filling process.

The black handle can be rotated to adjust the filling volume during production. The cylinder also features a detailed scale, making it easy to adjust the filling volume.

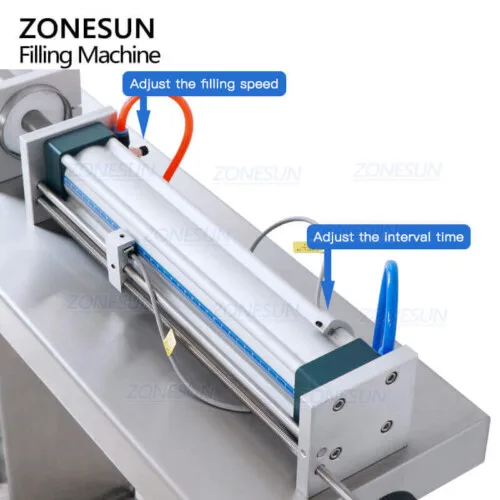

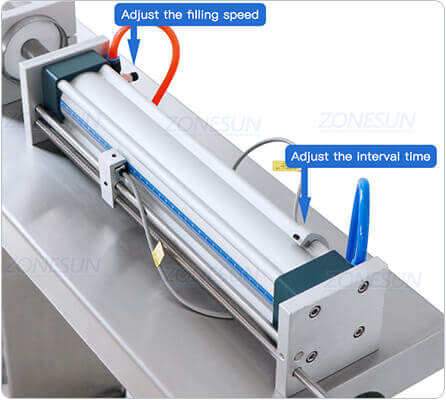

The diving nozzles' filling speed can be individually adjusted using the left knob. Additionally, the right knob allows you to set the interval time, enabling the machine to function automatically without the need for a pedal switch.

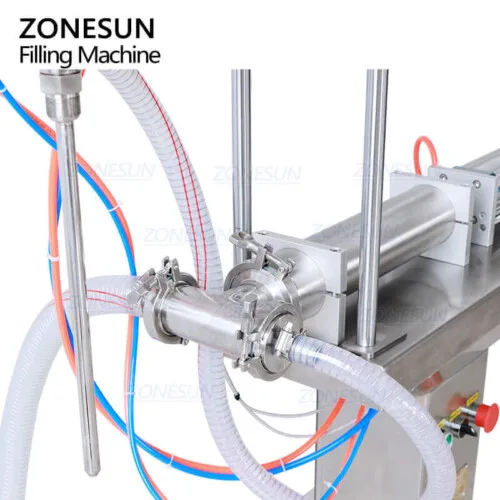

The container design helps reduce agitation and foam formation during filling, ensuring cleaner and more accurate fills, particularly for foamy liquids.

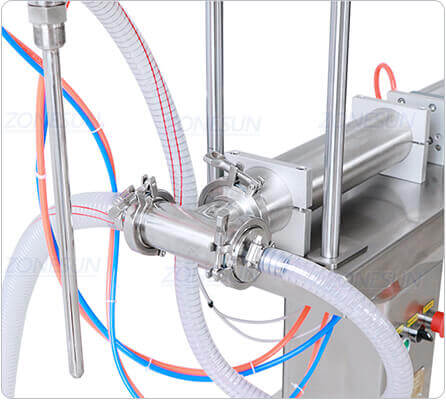

The filling valve is designed to prevent back pressure-induced reverse liquid flow, ensuring smooth operation and preventing any disruption to the flow of your materials.

The bottle holder's height can be adjusted by turning the screw, ensuring compatibility with bottles of various sizes.