Powder Vials Filling Capping Machine

Produst Description:

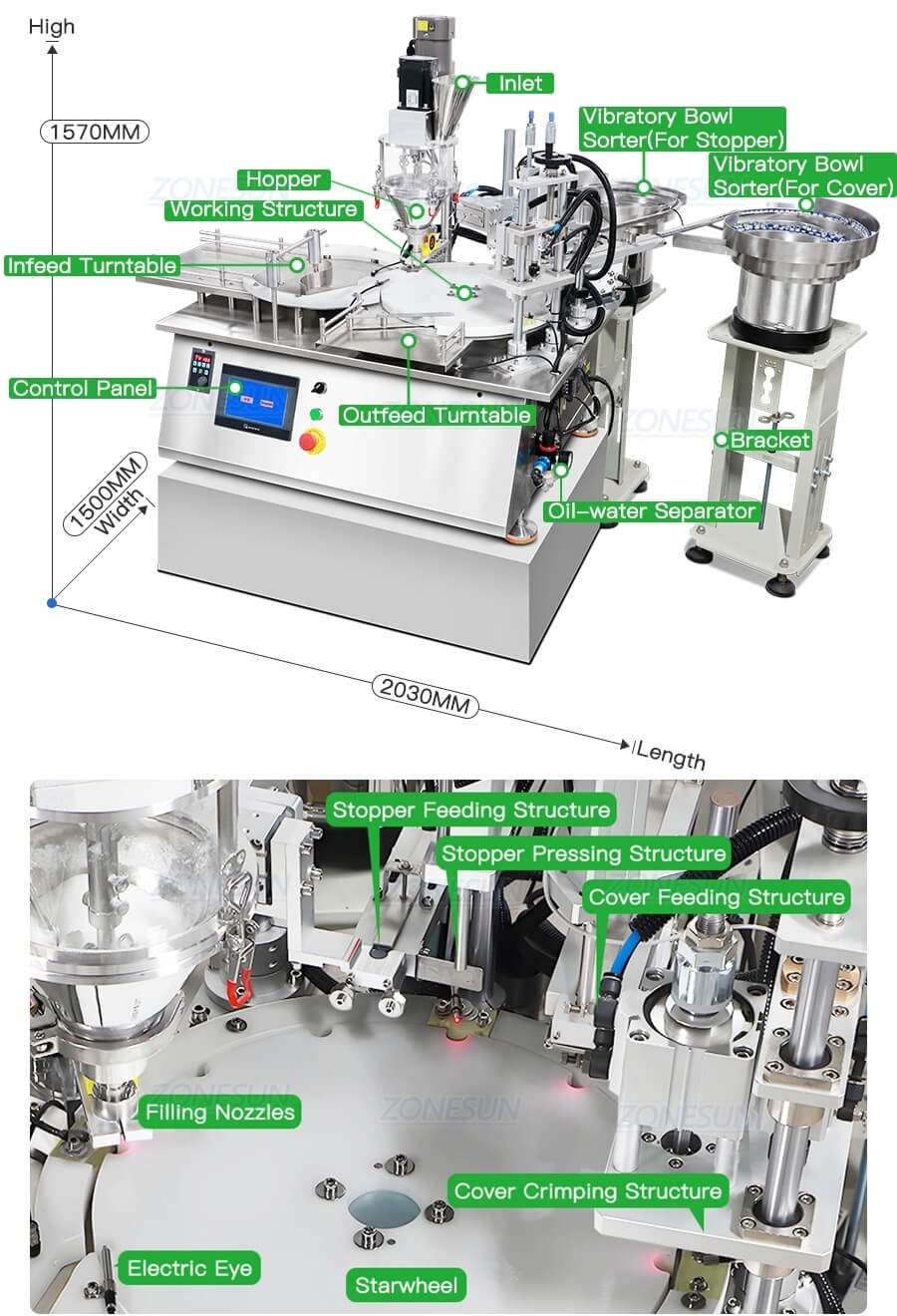

Powder vial filling capping machine features a compact design that minimizes workspace requirements. It seamlessly integrates bottle sorting, powder filling, stopper pressing, and flip-off cap crimping in a single unit. Widely utilized in cosmetic and chemical industries, this all-in-one solution enhances production efficiency.

Product Parameters:

|

Machine model

|

ZS-AFC20F

|

|

Power

|

110/220V 50-60HZ 1800W

|

|

Recommend Filling Range

|

0.15g-5g (Customizable)

|

|

Working capacity

|

15-20BPM

|

|

Hopper size

|

2L

|

|

Suitable bottle size

|

φ=15-30mm, H=35-60mm

|

|

Suitable cap size

|

φ=10-25mm

|

|

Machine size

|

About 2030*1500*1570mm

|

|

Package Size

|

About 1100*960*1250mm(Main machine)

About 750*440*720mm(Bracket) About 980*560*570mm(Vibratory bowl) |

|

Package Weight

|

About 385kg

|

Product Details:

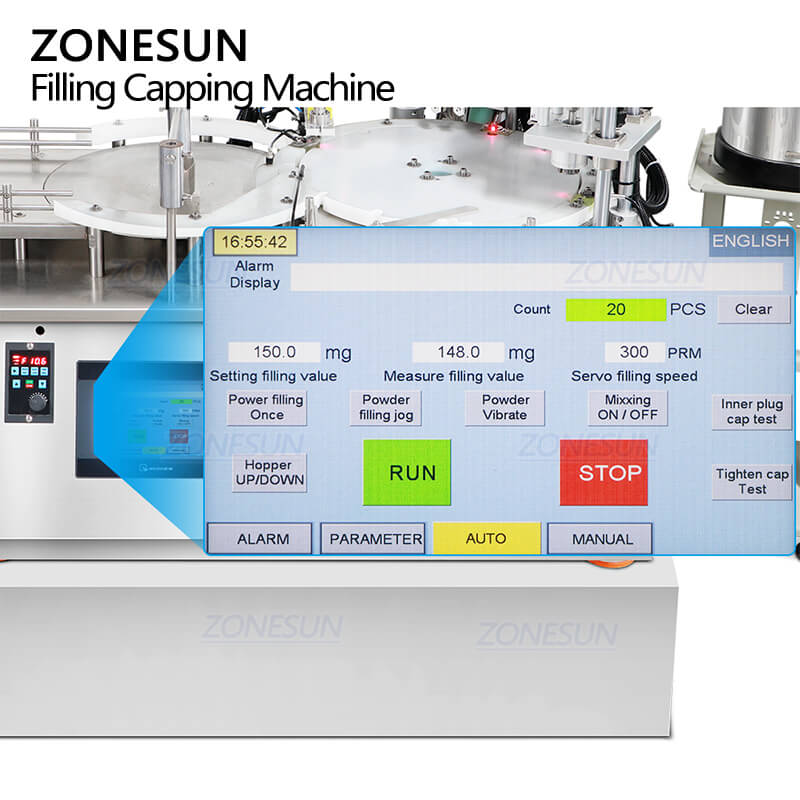

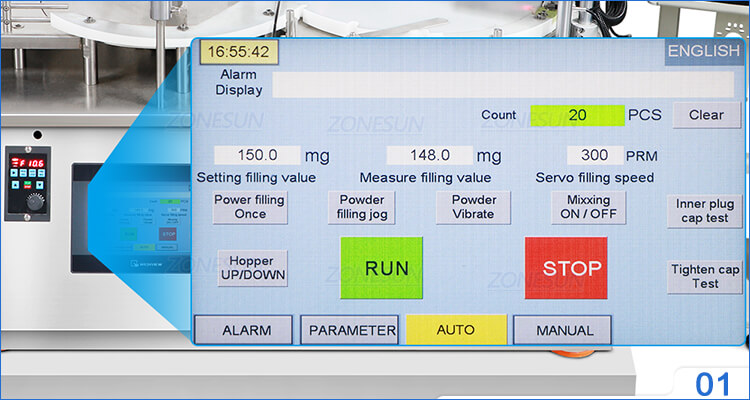

Touchscreen Control Panel

User-friendly interface allows for easy operation and parameter adjustment.

Infeed Turntable

Helps organize and smoothly feed vials into the filling station.

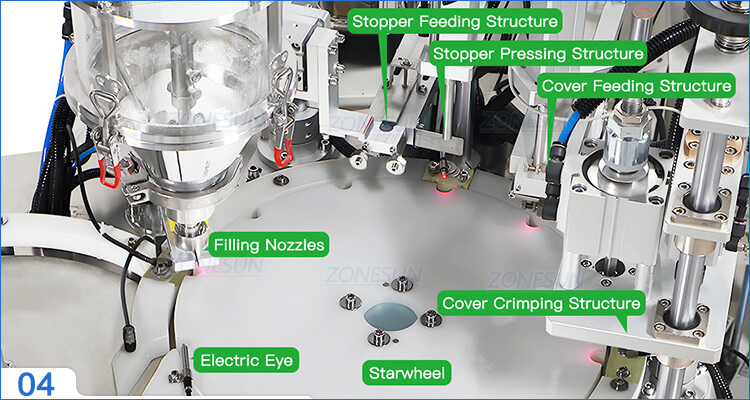

Auger Filling Mechanism

Ensures accurate and consistent powder dosing for each vial, hopper size is customizable.

Integrated Rotary Worktable

Central turntable coordinates all working stations for efficient operation.

Vibration Bowl for Cap & Stopper Sorting

Automatically orients and delivers inner stoppers and outer caps for placement.