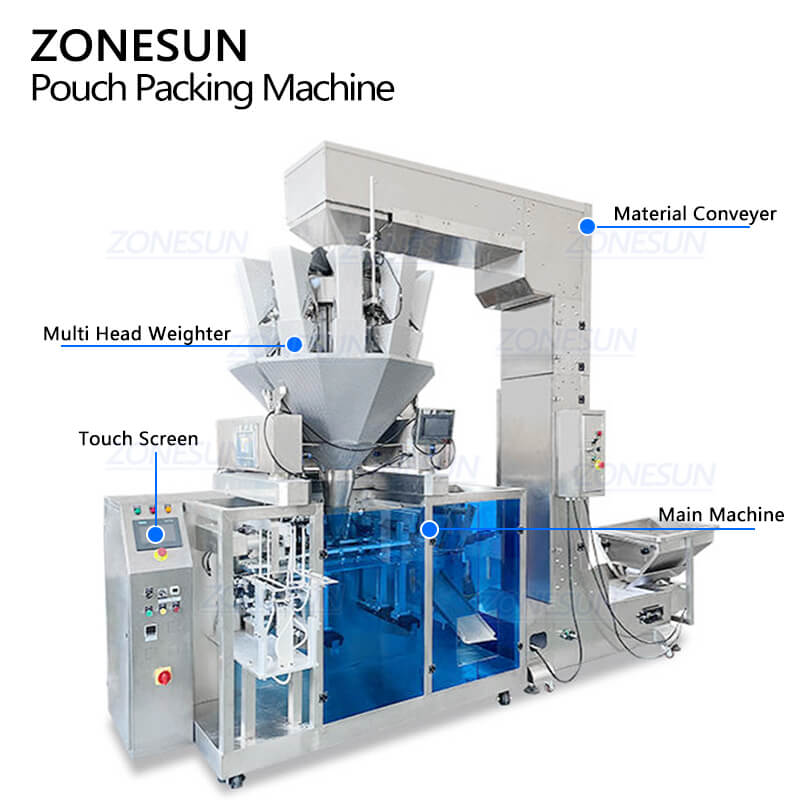

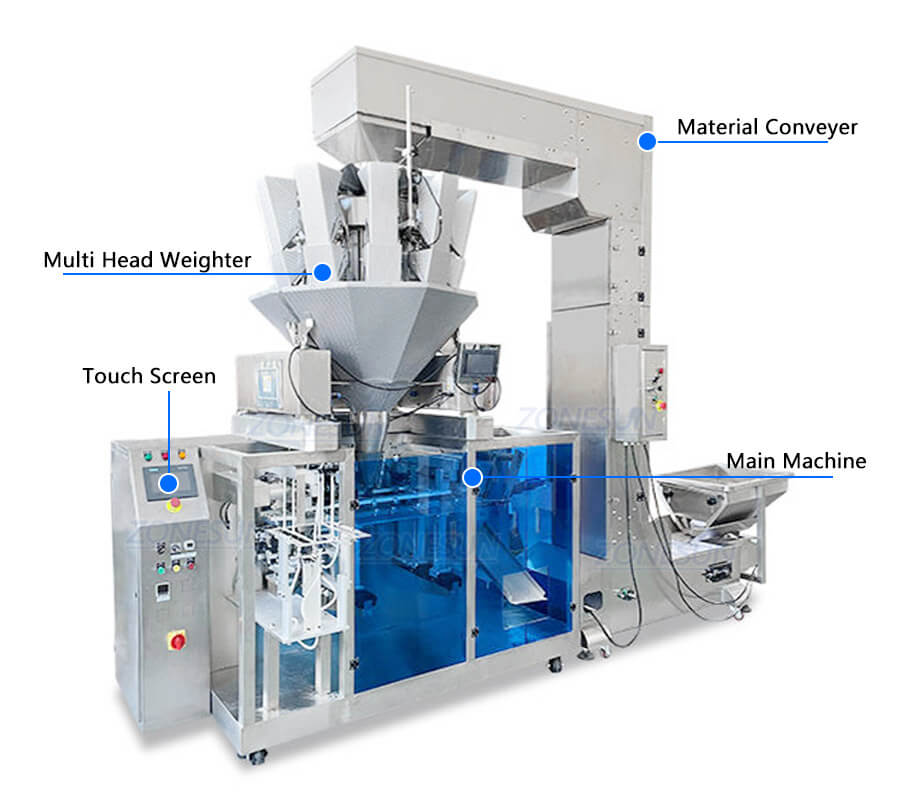

Granule Weighing Pouch Filling Sealing Machine

Product Description:

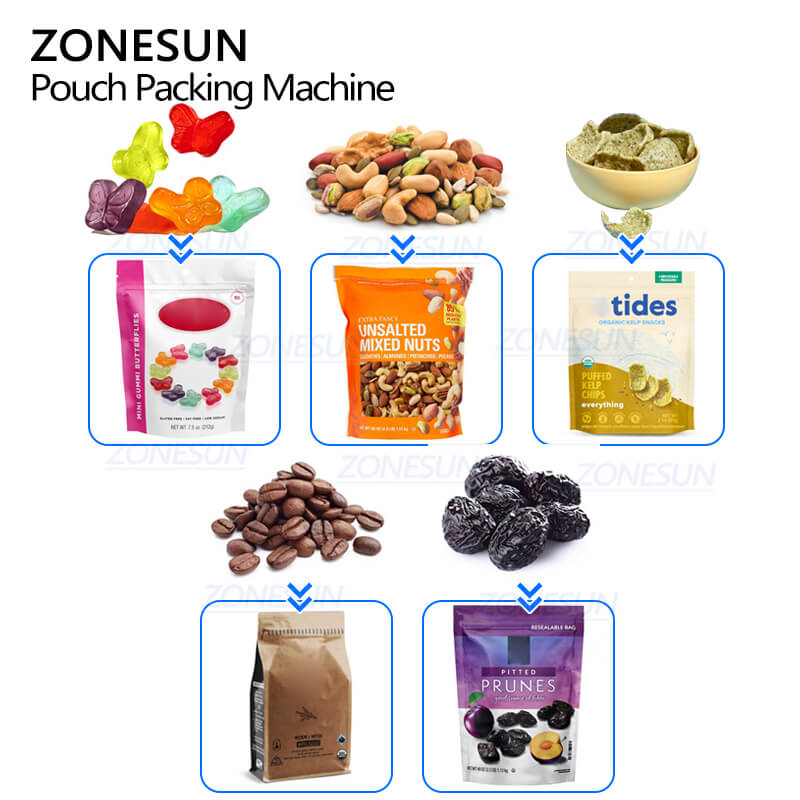

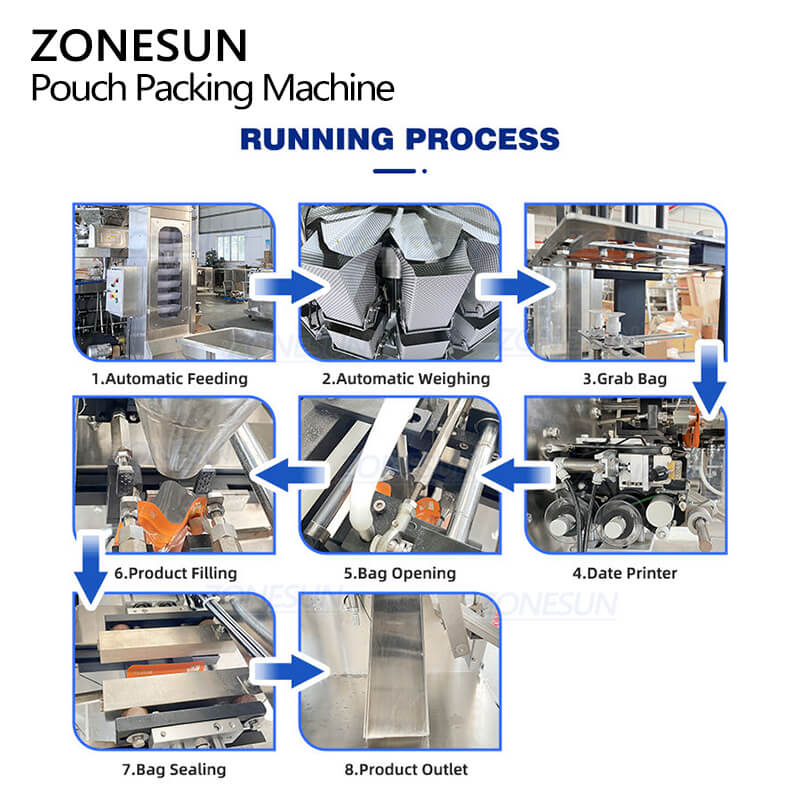

This fully automated bagging system efficiently packages granular, lump, flake, and bar-shaped solid materials at speeds of 30-60 bags per minute. The system seamlessly integrates a Z-type elevator, multi head weigher, and horizontal form-fill-seal machine. Material is elevated and precisely weighed before being dispensed into pre-made bags. The process includes bag opening via vacuum suction cups, vibration-assisted filling to prevent clogging, coding, heat sealing, and final product output. Driven by servo motors, this system ensures consistent accuracy and high throughput, maximizing your production efficiency.

Product Parameters:

| Model | ZS-GW150D | ZS-GW200D | ZS-GW250D | ZS-GW320D |

| Bag width(mm) | 80-150 | 90-200 | 150-250 | 200-320 |

| Bag length(mm) | 100-210 | 110-330 | 150-400 | 150-500 |

| Packing speed | 20-60bags/min | 20-60bags/min | 10-60bags/min | 10-50bags/min |

| Power supply | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Machine power | 2.5kw 50Hz | 3.5kw 50Hz | 3.5kw 50Hz | 2.5kw 50Hz |

| Gas consumption | 0.35m³ | 0.5m³ | 0.7m³ | 0.7m³ |

| Machine size(mm) | 1700*1050*1100 | 2150*1350*1300 | 2450*1200*1200 | 2800*1200*1200 |

| Machine weight | 600KG | 900KG | 1100KG | 1500KG |

| The application type bag | 3-sided bag, 4-sided bag, pillow bag, standing bag, M bags, special bag | |||

Product Details:

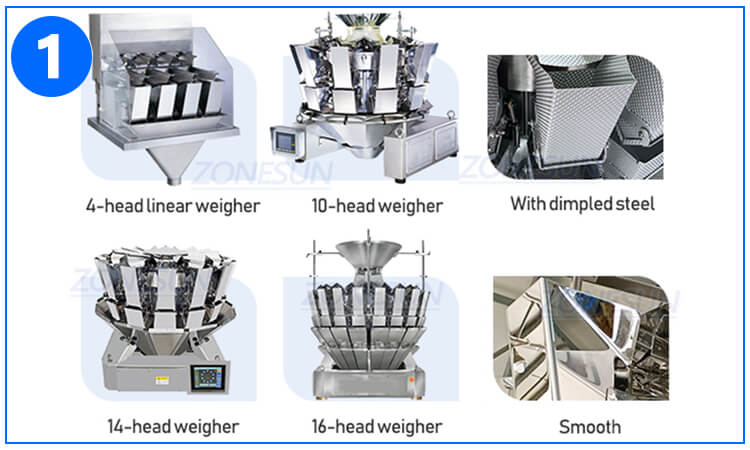

Multi Head Weigher

Multiple weighing heads simultaneously weigh small portions of the product combining them to achieve the target weight with high precision. It can be customized with dimpled or smooth steel.

Material Conveyor

The elevator gently lifts the product from the hopper to the multi head weigher. Customization for a slope conveyor is available.

Pouch Feeding

The pouches are stored at an adjustable rack, which is flexible and convenient for pouches of different sizes.

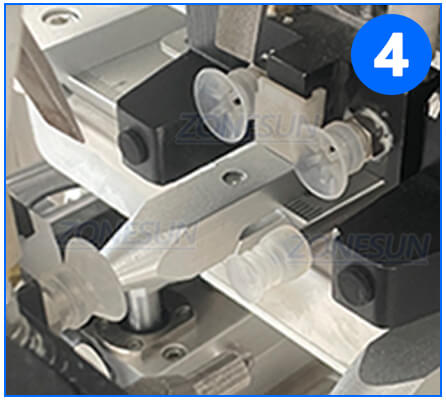

Vacuum Suction Cups

These cups gently open the pre-made bags, ensuring a clean and efficient opening process.

Vibration-Assisted Filling

This helps prevent clogging, especially with materials that tend to clump or stick together.

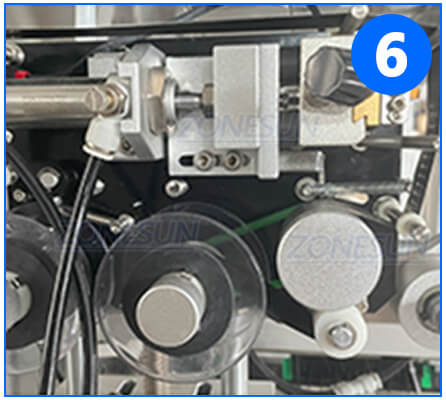

Date Printer

The coding process is integrated after the bag is feeding. This allows for clear and accurate.