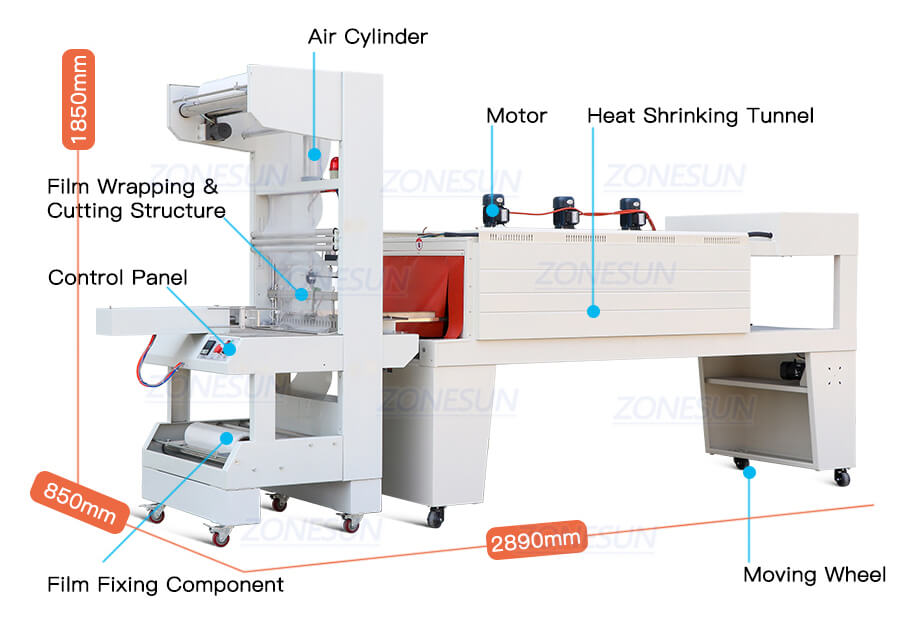

Film Cutting Shrink Packing Machine

Product Description:

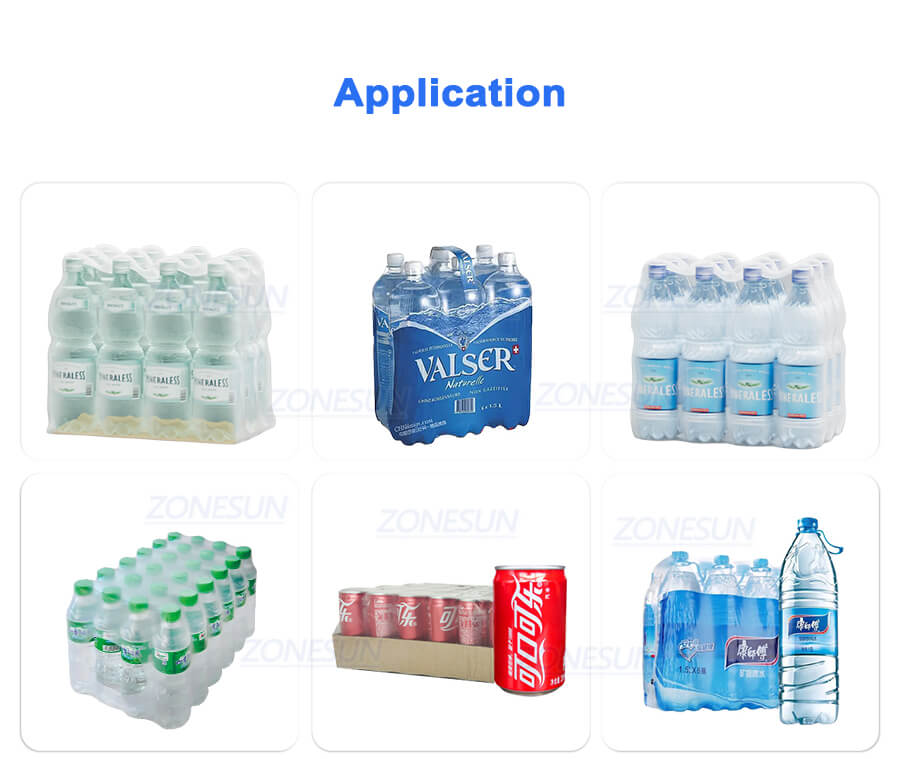

This packaging system consists of a semi-automatic film wrapping machine and a heat shrinking tunnel. It’s ideal for cans, mineral water, beer, glass bottles, beverages, and other containers with or without a bottom support, ensuring a perfect packaging effect.

Product Parameters:

Film Wrapping Machine

|

Machine Model

|

ZS-QZD7040

|

|

Voltage

|

220V, 50-60Hz

|

|

Power

|

2.2Kw

|

|

Packing speed

|

0-8 Packs/min(based on products)

|

|

Bottle size

|

Diameter:60-120mm Height:100-330mm

|

|

Max package size

|

500* 330*360mm(L*W*H)

|

|

Min package size

|

120*120*100mm(L*W*H)

|

|

Payload

|

20kg(can be customized)

|

|

Film roll width

|

Max 650mm

|

|

Film thickness

|

0.03-0.25mm

|

|

Applicable shrink film

|

Only PE Film

|

|

Machine size

|

About 1000* 900* 1900mm

|

|

Machine weight

|

About 240kg

|

Heat Shrinking Machine

|

Machine Model

|

ZS-BSPN6040

|

|

Voltage

|

380V 50-60HZ

|

|

Power

|

21KW

|

|

Tunnel Size

|

About 1800*600*400mm

|

|

Conveying Speed

|

0-15m/min

|

|

Transport Load

|

<35kg

|

|

Suitable Film

|

PVC/POF/PE

|

|

Machine Size/Package Size

|

About 2800*910*1400mm/2880*930*1500mm

|

|

Machine Weight/Packgae Weight

|

About 207kg/350kg

|

Product Details:

Simple control panel is more convenient to adjust the working parameter like heating temperature and time. The leakage protection device can ensure the safety operation.

The film cutting and wrapping are integrated, working height and width can be adjusted according to package items. It has sharp cutting blade which can ensure the film can be cut neatly and improves production quality.

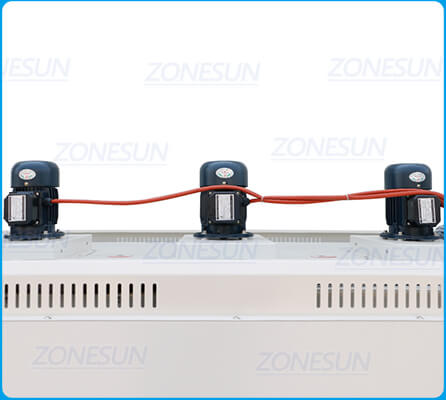

The high-power motor has strong wind power, this can ensure the package film can be shrinked evenly. Different sizes of heating tunnel can be customized as production need.

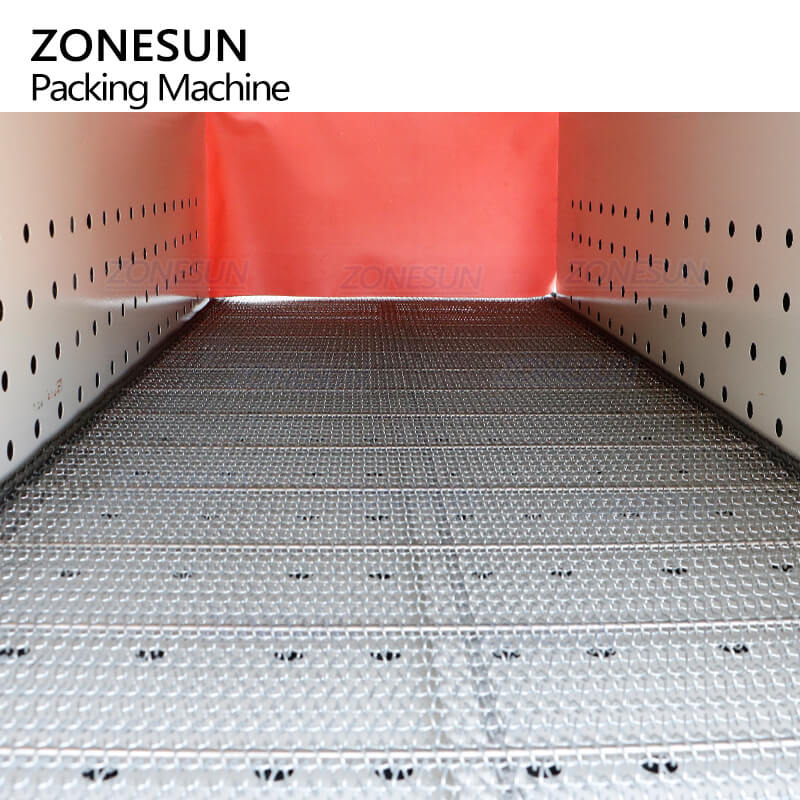

The upgraded version of the conveyor belt transport the goods more smoothly, effectively improves the package quality and work efficiency.