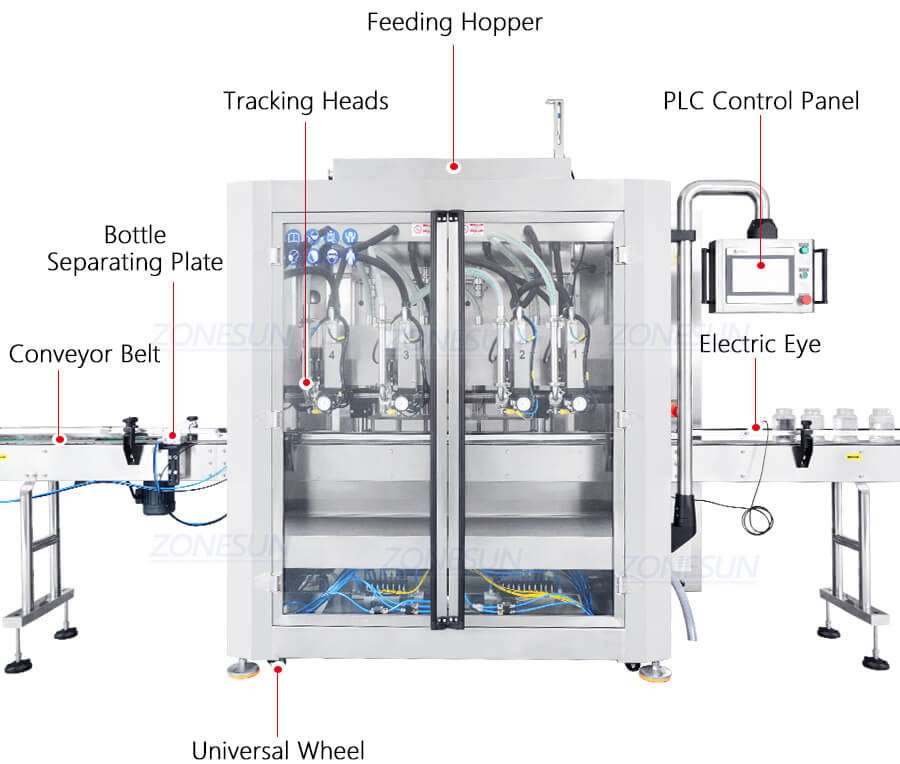

Automatic Tracking Filling Machine

Product Description:

This machine is equipped with servo motor and you just need to enter the certain number to adjust filling range.Compared with other filling machine,this tracking type filling machine can control filling nozzle follow moving bottles during filling work.It reduce production error and improve filling accuractely.It is designed for filling paste like curry paste,tomato sauce,pepper sauce,each nozzle can be controlled separately.

Product Parameters:

| Machine Model | ZS-VTPF4 |

| Voltage | 380V/220V/110V |

| Power | 6kW |

| Filling Head | 4 Heads |

| Filling Range | 500-5000ml (Can be customized) |

| Filling Speed | 2000-5000bottles/hour(depend on material and bottle size) |

| Filling Accuracy | ±1% |

| Air Pressure | 0.6-0.8Mpa |

| Air Consumption | 6-7m³/min |

| Machine Material | Stainless Steel |

| Machine Size | About 3000*1500*2700mm |

| Machine Weight | About 900kg |

| Main Configurations | ||

| Name | Origin | Brand |

| Plc | Shenzhen | Cotrust |

| Touch Screen | Shenzhen | Cotrust |

| Intermediate Relay | Japan/China | Omron/APT |

| Pneumatic Components | Taiwan | Airtac |

| Fiber Optic Sensor | Germany | Leuze |

| Servo Motor | Shenzhen | Cotrust |

Product Details:

PLC Control Panel

With touch screen panel, it’s easy to set parameters and control the machine.The language of panel can be customized according to customers’need.

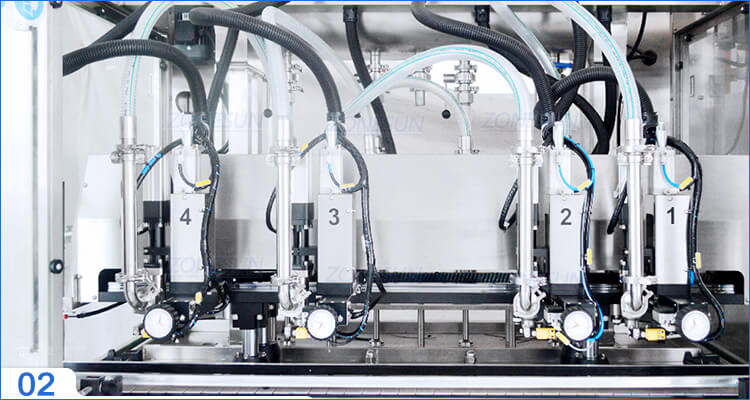

Tracking Heads

Filling heads of the machine can move as bottles move during filling, improving efficiency.

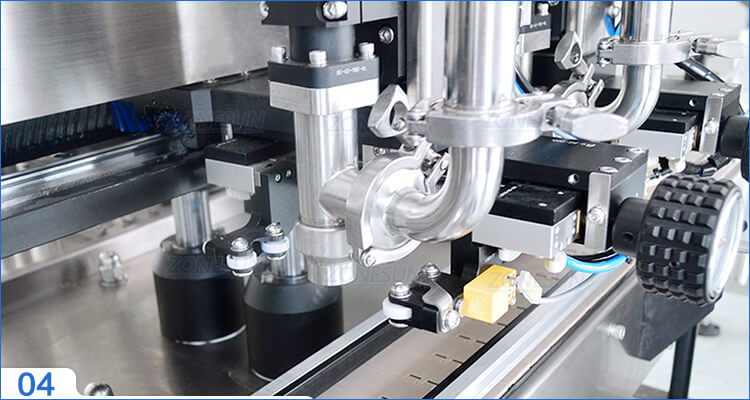

Neat Wiring

Neat wiring helps to reduce issues such as interference,crossovers, and short circuits between wires,improving stability.

Servo Motor

The filling speed is fast,the stability is good,and the filling is controlled by a servo motor,ensuring high filling accuracy.