Tabletop Test Tube Filling Capping And Labeling Machine

Product Description:

This tabletop test tube packaging system is a compact, automated packaging system designed for the small-scale, efficient processing of test tubes. These machines are typically used in laboratories, research facilities, and small production environments where space is limited.

Product Parameters:

Filling Capping Machine

| Machine Model | ZS-AFC35 |

| Voltage | 220V 50-60Hz |

| Power | About 400W |

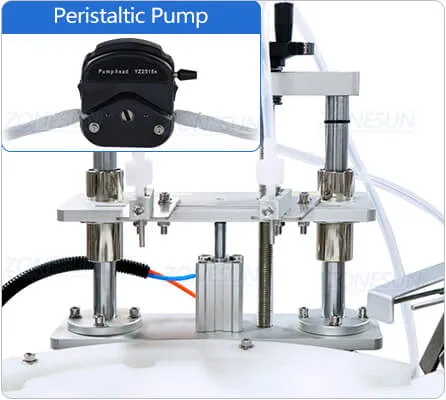

| Filling Pump | Peristaltic Pump |

| Production Capacity | About 10-15pcs/min(depending on liquid and bottle size) |

| Filling Range | Customized |

| Filling Accuracy | ±≤1% |

| Suitable Bottle Size | Customized |

| Air Pressure | 0.4-0.6MPa |

| Machine Size | About 1800*750*1020mm |

| Package Size |

About 750*680*1130mm(Vibratory Bowl Sorter)

About 420*750*990mm(Lift Table For Vibratory Bowl Sorter)

About 860*1190*820mm(Filling Capping Machine)

|

| Package Weight |

About 111kg(Vibratory Bowl Sorter)

About 61kg(Lift Table For Vibratory Bowl Sorter)

About 159kg(Filling Capping Machine)

|

Horizontal Labeling Machine

|

Machine Model

|

ZS-TB800

|

|

Machine Voltage

|

110/220V 50-60HZ

|

| Working Speed | About 30-50bottles/min |

| Label Object Size | H≤150mm φ≤10-30mm |

| Label Size | 15-150mm (H) |

| Roll Inside Diameter (mm) | φ76mm |

| Roll Outside Diameter (mm) | φ350mm |

| Machine Size | About 1500*600*940mm |

| Machine Weight | About 145kg |

Product Details:

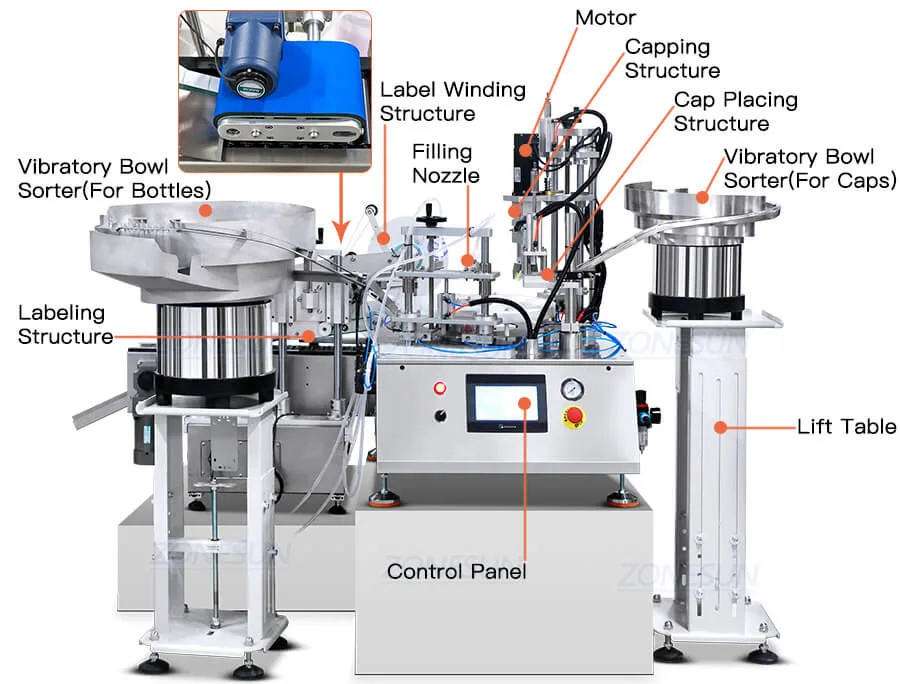

With 2 filling heads operating simultaneously, more containers can be filled in a shorter amount of time. The filling work is controlled by peristaltic pump, liquid being pumped only contacts the interior of the tubing, minimizing the risk of contamination.

The precise control and automated handling reduce the likelihood of misfeeds, minimizing downtime and increasing overall productivity. The size of starwheel is customized according to container size.

Servo motors provide precise control over the torque applied during the capping process. This ensures that each cap is tightened to the exact specification, reducing the risk of under- or over-tightening.

The bowls and tracks can be customized to meet specific needs, accommodating different parts and ensuring precise handling. They ensure that components, such as caps or containers, are consistently oriented in the correct position.

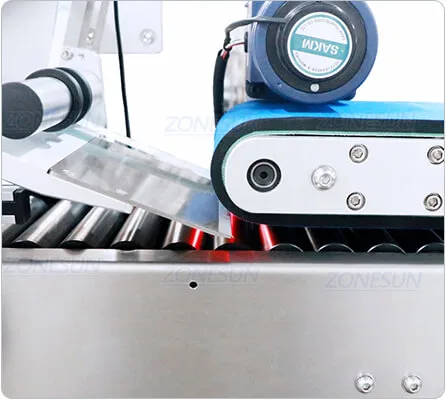

This kind of labeling structure is designed for higher speed operations, it can handle continuous labeling tasks without frequent interruptions and maintains label placement on each test tube, reducing the risk of misaligned or skewed labels.

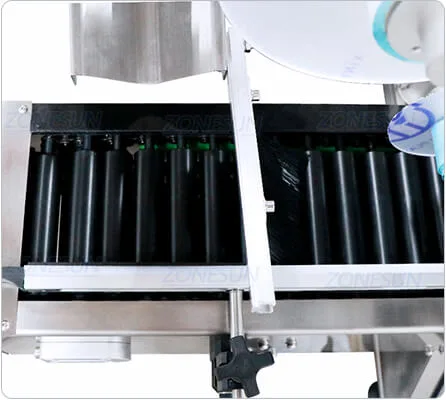

This labeler machine can be easily integrated with filling and capping machine to create the efficient production line, roller conveyor can be customized for accommodating different test tube sizes and diameters.