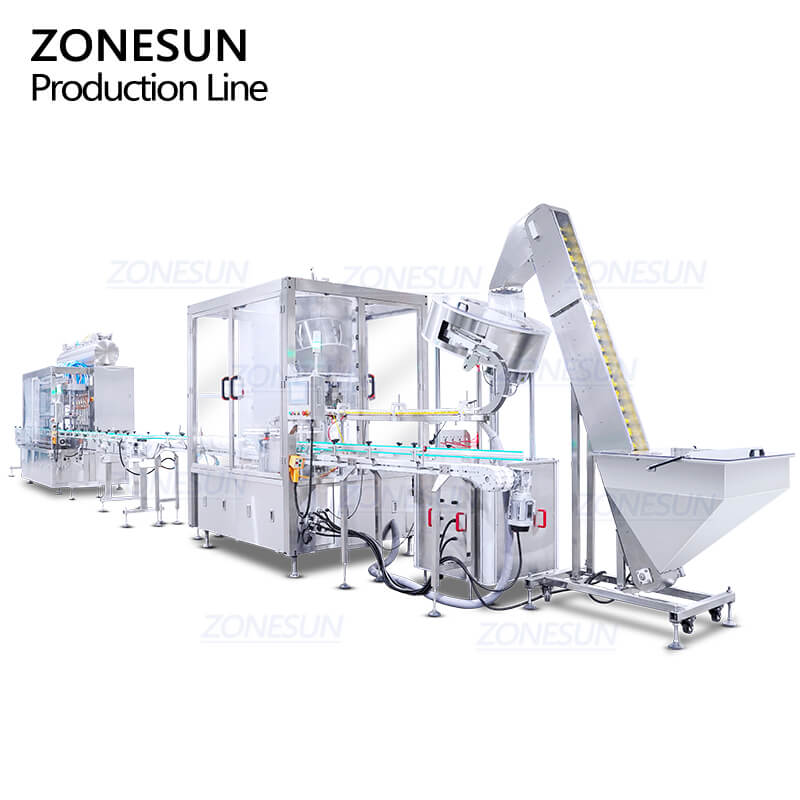

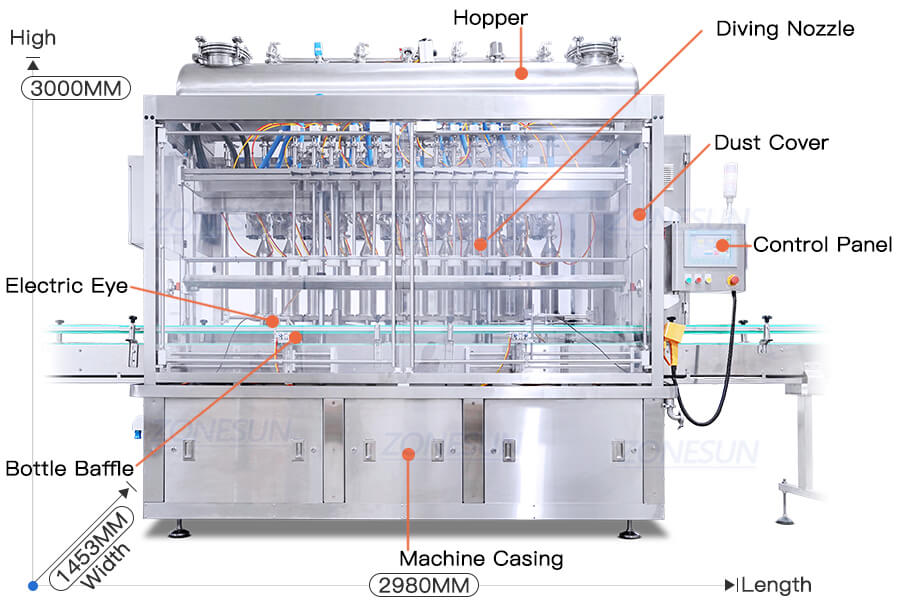

High Speed Oil Filling Capping Machine

Product Description:

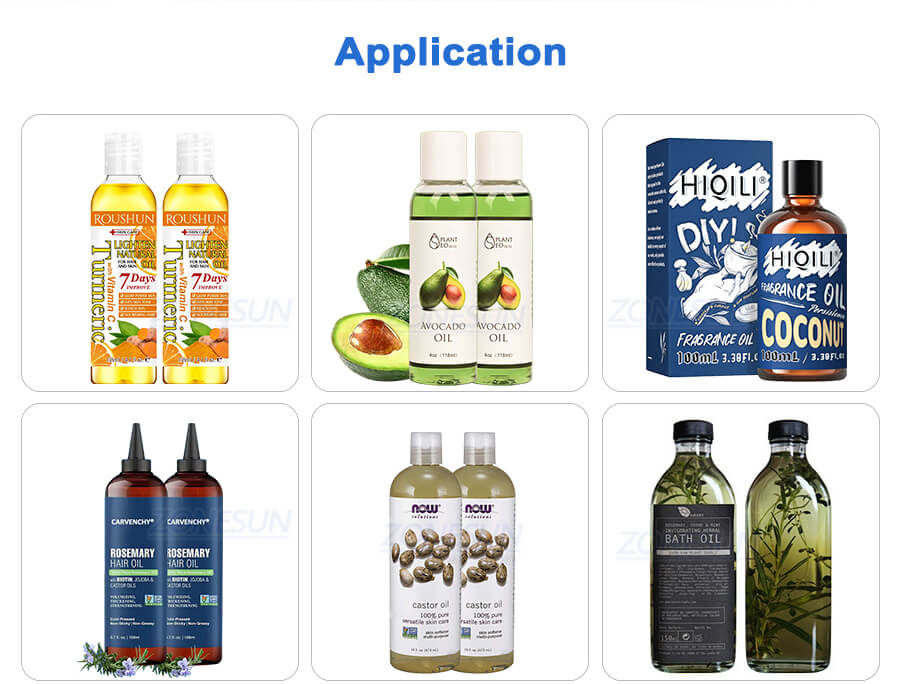

This filling system consist of 16 heads filling machine and 12 heads capping machine, working capacity can reach 100BPM, it suits medium and large scale production of cooking oil, motor oil.

Product Parameters:

16 Heads Piston Pump Filling Machine

| Machine model | ZS-SOPP16 |

| Voltage | 3-phase 380V, AC, 50HZ |

| Application | 500-1000ml |

| Filling pump | Piston Pump |

| Packaging size | φ=60-150mm H=250-350mm (customizable) |

| Filling accuracy | ≤±3g(500-1000ml) |

| Production capacity | ≥4800 BPH (based on 1000ml detergent) |

| Air pressure | ≥0.5MPa |

| Gas consumption | ≤0.3 m³/minute(clean stable air pressure) |

| Main machine material | SUS304 & 316 |

| Noise | <78dB |

| Machine size | L2980mm*W1453mm*H3000mm |

| Machine weight | About 2000kg |

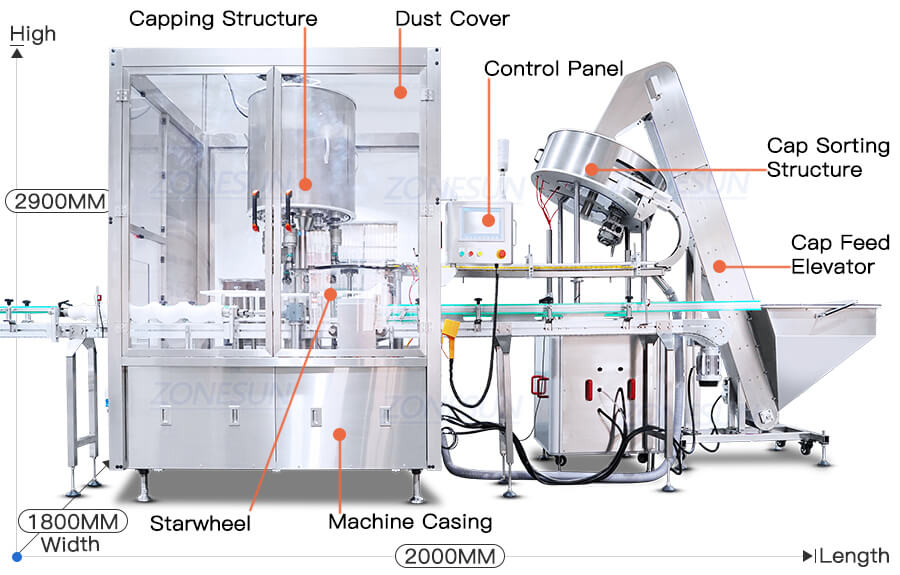

12 Heads Capping Machine

| Machine model | ZS-XG440QA |

| Number of capping heads | 12 heads |

| Power supply | 380V 50Hz 3KW |

| Air pressure | 0.5-0.6 Mpa |

| Production capacity | 85-115 BPM (based on product size) |

| Applicable cover size | Customized |

| Applicable bottle type | Customized |

| Cap torque control type | Permanent magnetic clutch |

| Noise | <80dB |

| Main machine material | SUS304 & 316 |

| Conveyor height | 900±50mm |

| Dimensions | 2000mm*1800mm*2900mm(L*W*H) |

| Weight | 3000kg |

Product Details:

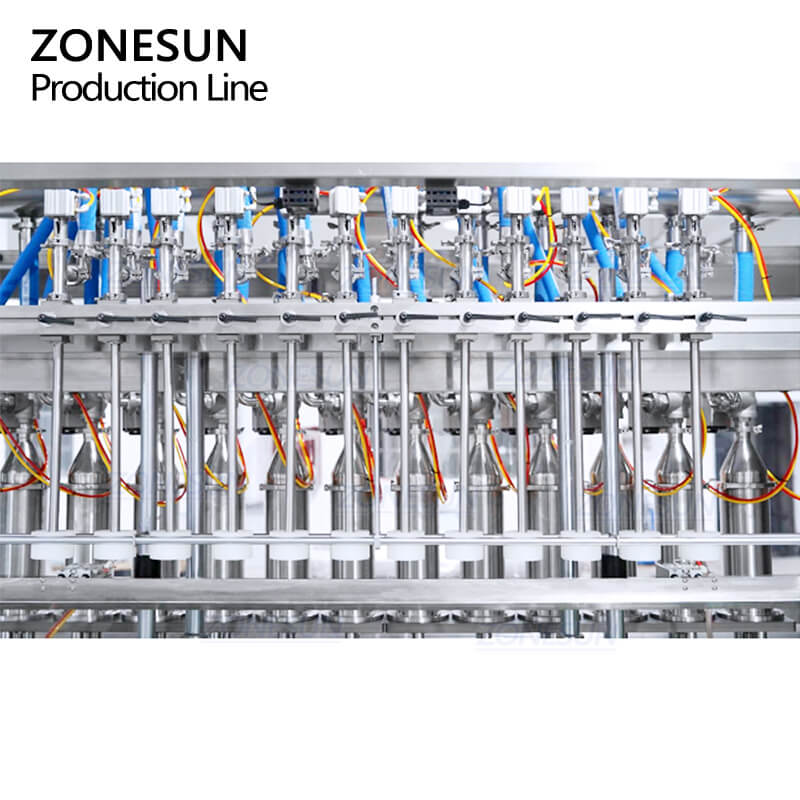

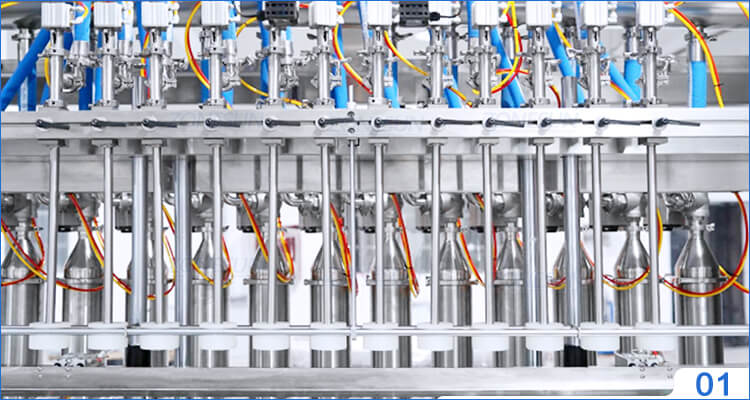

Diving Filling Nozzle

It features a diving filling nozzle to ensure high filling accuracy.

Storage Tank

The hopper is customizable according to demand to ensure that the filling material can be supplied in time.

Piston Filling Pump

One motor drives all piston rods to rise and fall simultaneously, it can slightly adjust the filling volume of each filling nozzle.

Control Panel

Touch screen makes it more intuitively to adjust machine,operation language is customizable.

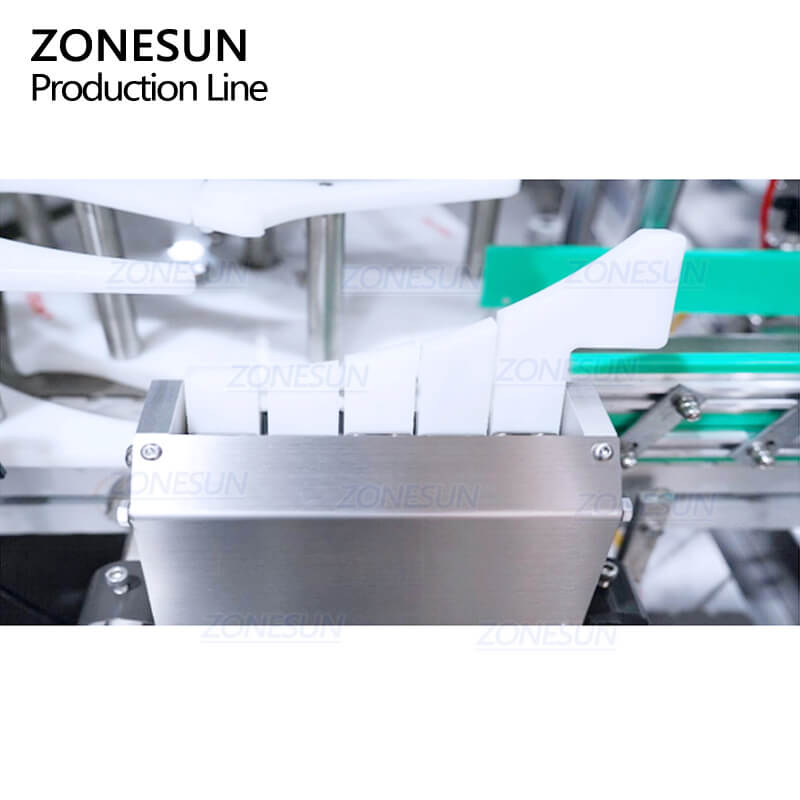

Capping Structure

The upper and lowerlimit detection photoelectric can prevent the lifting transmission mechanism from locking or disengaging.

Unqualified Products Detecting Structure

It can separate the qualified products and unqualified products to improves production quality.

Cap Feeding Structure

Suits regular round caps, it can arrange caps be in order and convey caps to the capping structure in time.