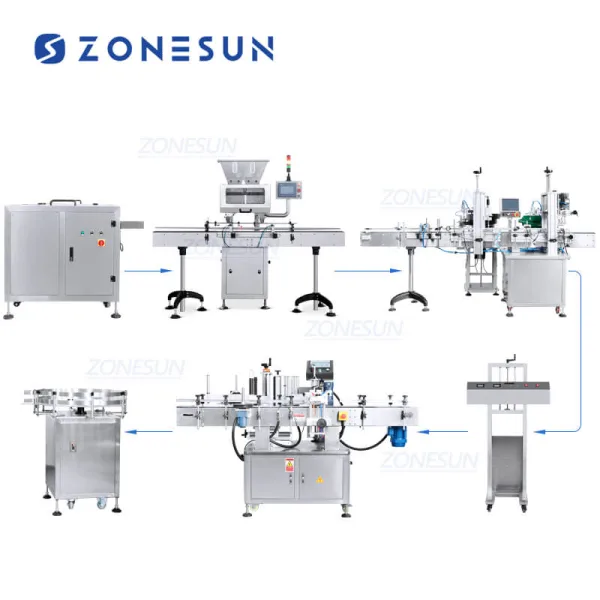

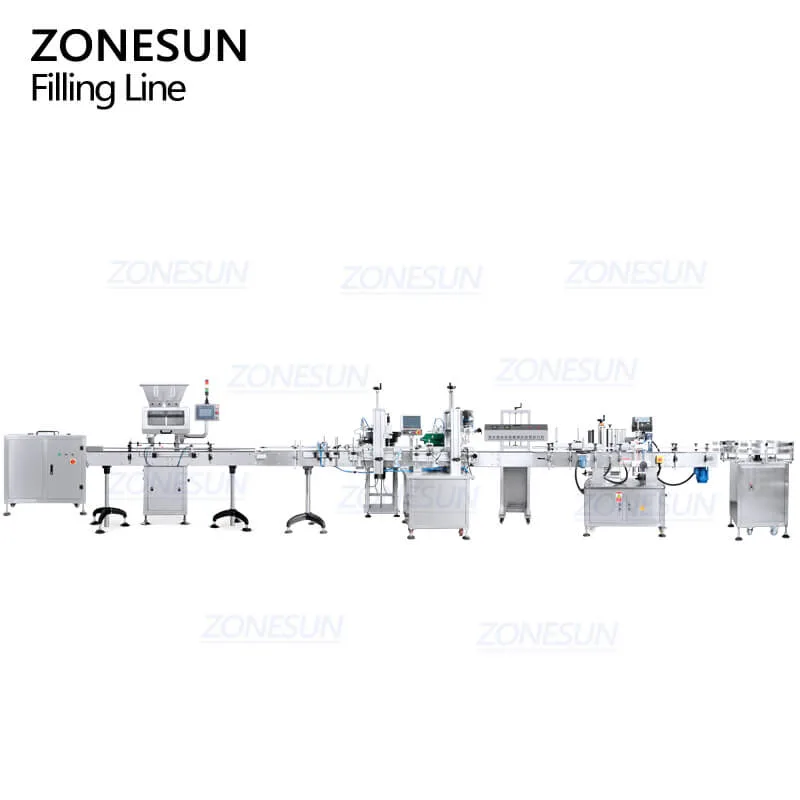

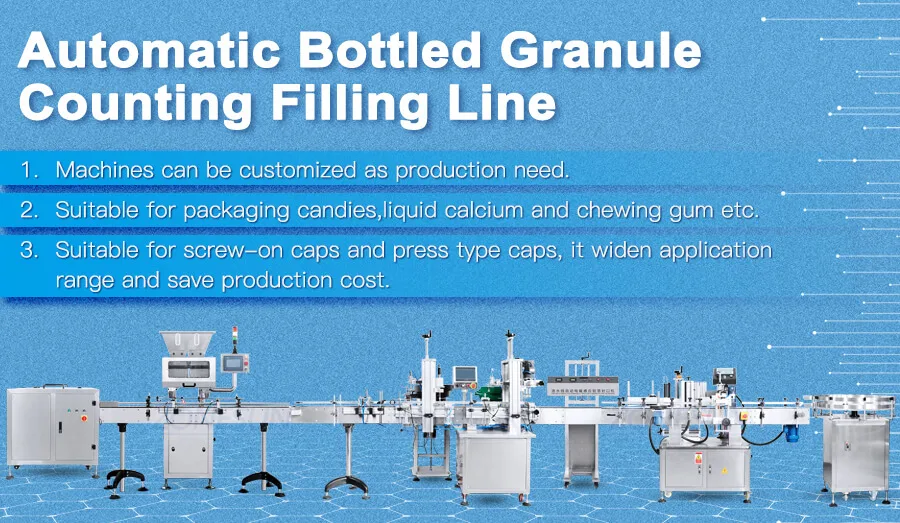

Automatic Granule Counting Bottles Filling Line

Product Description:

This automated filling system is designed for filling granule into bottles, sealing bottles, capping bottles and labeling self-adhesive stickers onto bottles. This filling line is suitable for food and cosmetics industries.

Product Parameters:

Granule Counting Machine

|

Machine model

|

ZS-JF70

|

|

Machine voltage

|

110/220V 50-60HZ

|

|

Granule size

|

Customized

|

|

Filling range

|

1-9999pcs/bottle

|

|

Working speed

|

40-100bottles/min(based on filling range)

|

|

Filling accuracy

|

≥99.5%

|

|

Air pressure

|

0.6MPa

|

|

Machine size

|

About 1360*1500*1680mm

|

|

Machine weight

|

About 550kg

|

Capping Machine

|

Machine model

|

ZS-XG17DV

|

|

Working voltage

|

AC220V/110V 50- 60HZ

|

|

Bottle height

|

30-300mm

|

|

Cap diameter

|

18-70mm

|

|

Bottle diameter

|

20-160mm

|

|

Caps type

|

Screw-on caps & Press type caps

|

|

Working speed

|

15-20 bottles/min

(depending on bottle and cap size and shape)

|

|

Working pressure

|

0.4-0.6MPa

|

|

Package size

|

About 1720*820*1770mm (Main Machine)

About 1170*580*1170mm(Vibratory Bowl Sorter)

|

|

Package weight

|

About 268kg (Main Machine)

About 187kg(Vibratory Bowl Sorter)

|

Sealing Machine

|

Machine model

|

ZS-FK4200V

|

||||

|

Power supply

|

220V 50HZ 4200W

|

||||

| Sealing diameter |

15-60mm

|

20-70mm

|

35-85mm |

50-120mm

|

60-130mm

|

| Sealing speed | 0-260bottles/min(based on bottle size) | ||||

| Suitable bottle height | 10-300mm(based on 900mm height conveyor belt) | ||||

|

Machine size

|

About 700*690*1450mm

|

||||

| Machine weight | About 43kg | ||||

| Package size | About 850*650*1590mm | ||||

|

Package weight

|

About 92kg

|

||||

Labeling Machine

| Model | ZS-TB260 Labeling Machine |

| Power supply | AC220V 50Hz/60Hz 1500W |

| Labeling capacity | 25-40PCS /min(depends on bottle size) |

| Labeling accuracy | ±1.0mm |

| Suitable Bottle Diameter | φ30-100mm |

| Label size | (L)15-200mm (H)15-150mm |

| Roll inside diameter | φ76mm |

| Roll outside diameter | φ350mm |

| Conveyor Size | 1950(L)*100mm(W) |

| Machine size | About 2000*1400*1300mm |

| Packing Size | About 2120*940*1500mm |

| Net Weight/Gross Weight | About 226kg/290kg |

Product Details:

All machines are equipped with PLC touch screen control panel, it shows machine working data more intuitively and this will be more convenient when debugging machine. Operation language can be customized as needed.

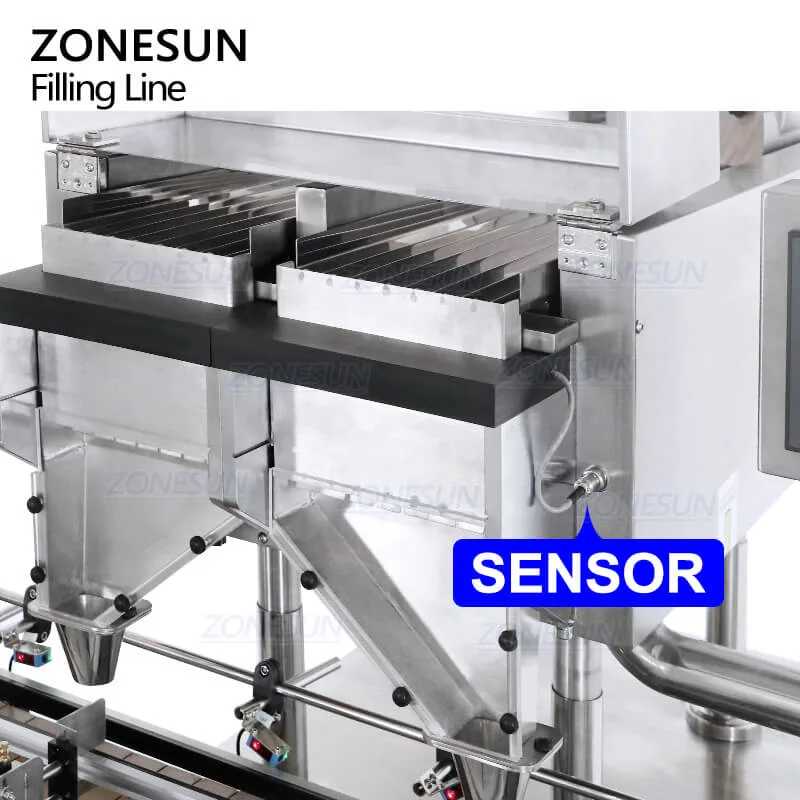

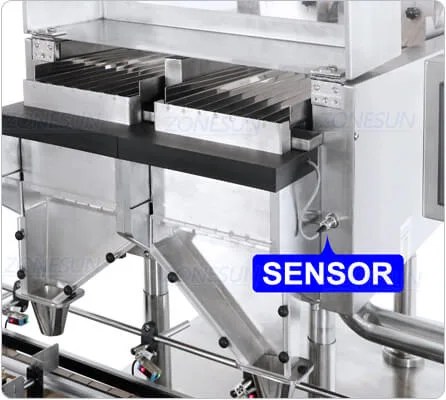

The feeding structure can ensures granule can be supplied in time, quantity of counting channel can be customized as production need. There is a sensor on both sides of the machine, which can ensure same number of granule will be filled into bottles automatically. Improve work efficiency.

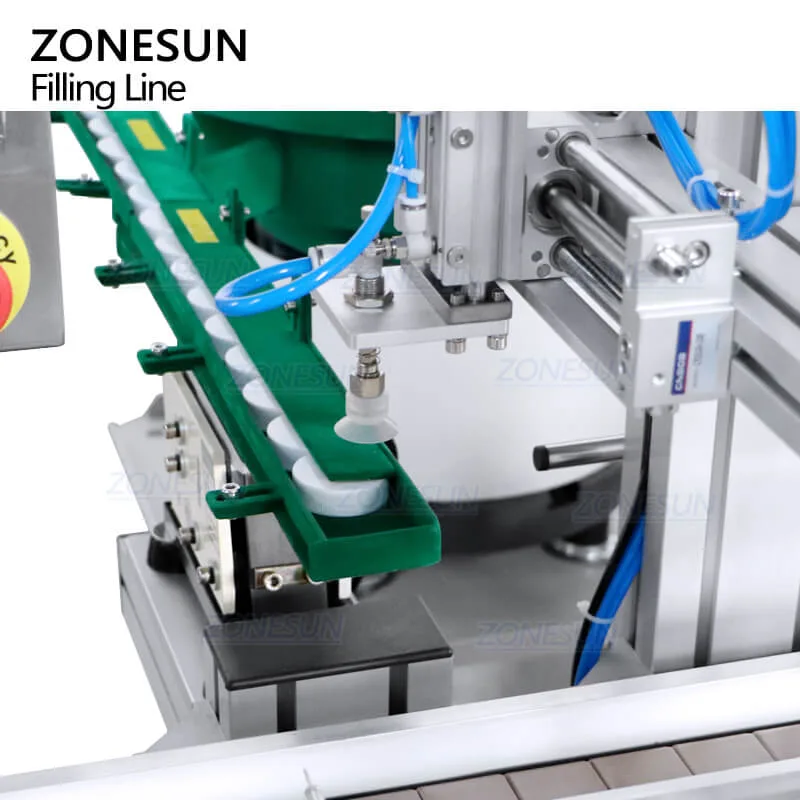

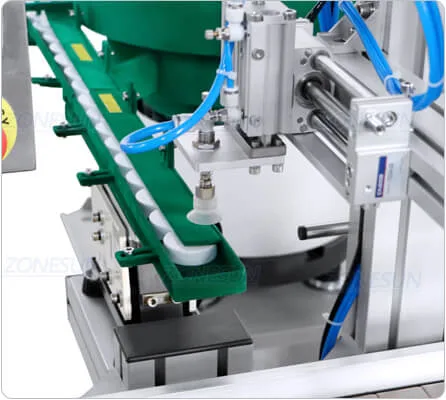

The air nozzle is suitable for moving caps to bottles, this kind of feeding method is suitable for irregular caps (the top of bottle caps must be flat),help to reduce production error.

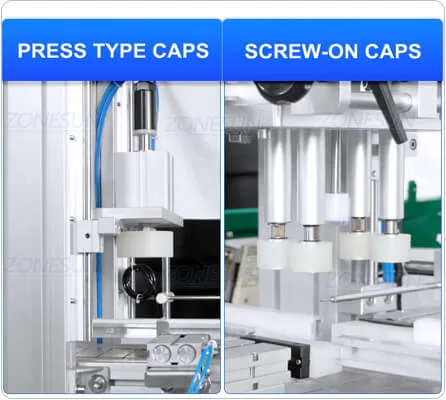

The capping machine is suitable for the screw-on caps and press type caps, it widen application range. Reasonable machine design helps to save working space and production cost.

The power of this machine can be controlled according to sealing effect. The closer the bottle is to the coil, the higher the sealing temperature.

Designed for labeling adhesive stickers on round bottles, this labeler machine is suitable for single side, double sides and wrap around labeling.

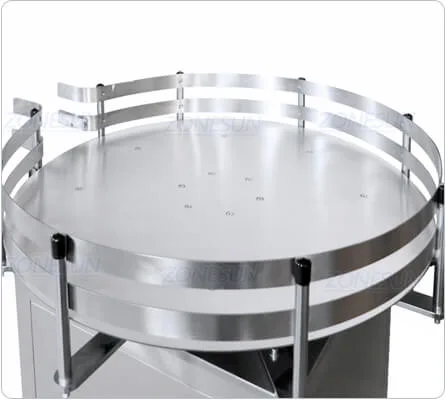

Connect with bottle turntable machine, it can collect finished products automatically, saving labor cost. Its running speed can be adjusted as production need. The diameter of turntable can be customized as needed.