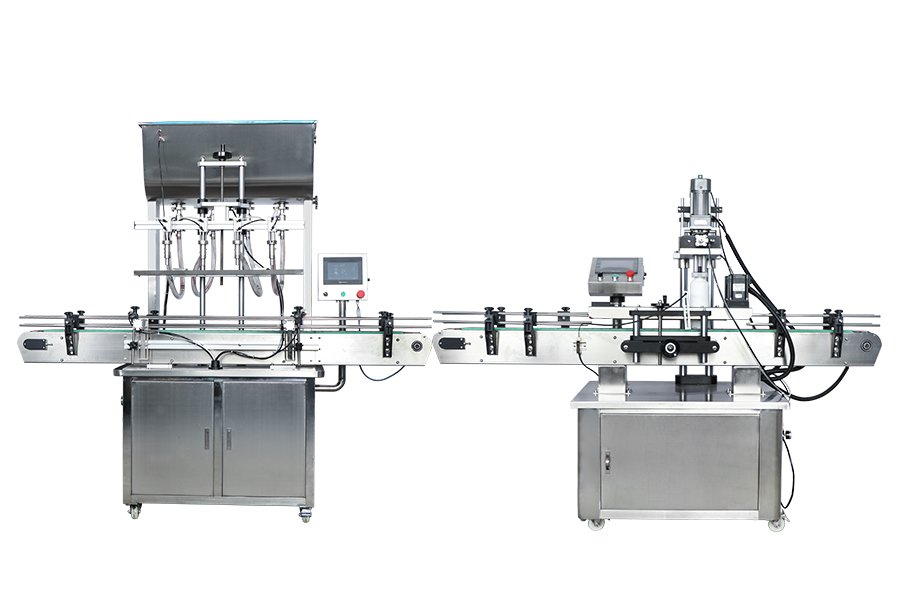

Installation and commissioning of machines de remplissage de pâte

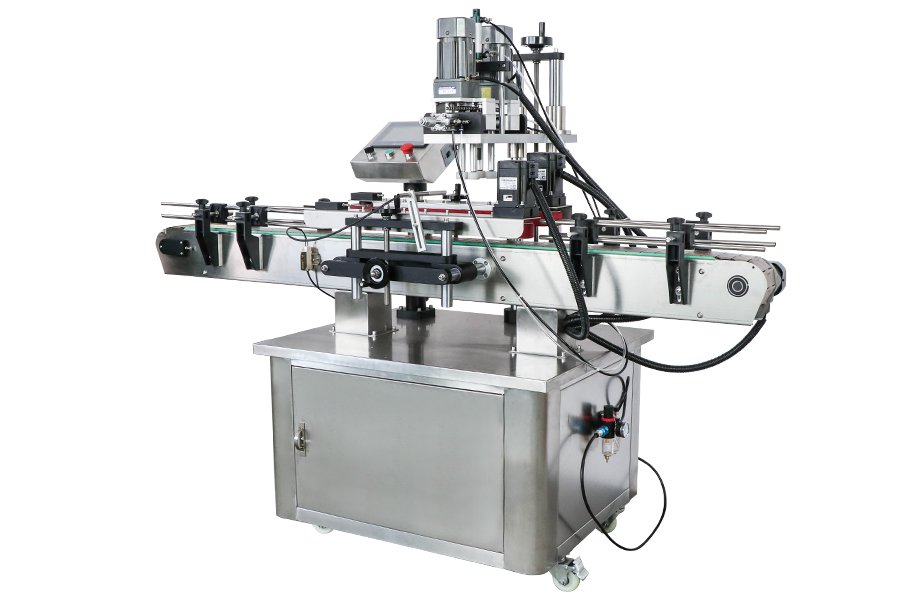

1. Une fois la machine déballée, installer selon le «Schéma de principe d'installation» et connecter la source d'air comprimé. La pression de la source de gaz est 0.6 MPa. Si la conduite principale d'air comprimé est connectée, la vanne doit être installée en premier.

2. Ouvrez la porte de droite et allumez le standard d'huile pour ajouter de l'huile spéciale propre ou de l'huile de machine à coudre. Remarque: N'apportez pas de pression d'air lors du ravitaillement. Il est conseillé d'augmenter le volume d'huile à 8 minutes. .

3. Passer la source d'air pour vérifier si les surfaces d'étanchéité fuient. Réglez la pression d'air sur 0.3 ~ 0.4 MPa to adjust the amount of oil. After spraying a few drops of oil, you can check the fuel injection regularly.

4.Réglage du volume de remplissage: first rotate the filling volume to adjust the hand wheel, observe the indication window scale to achieve the required filling volume, and adjust the suction and discharge speed to achieve a satisfactory filling effect. Volume and finally correct the filling volume.

Cleaning requirements

Wash thoroughly before operation. Wipe off oil or dirt with a soft non-woven cloth and detergent, then wipe dry with a soft non-woven cloth.

In accordance with GMP requirements, check whether the parts in contact with the equipment meet the corresponding cleanliness requirements. Sinon, clean and dry again. La méthode de nettoyage est basée sur les exigences du processus.

Operation and maintenance

1. The filling operation of the machine is divided into automatic and manual. When the height of the machine is manual, when the manual is used, you only need to push the tongue with the mouth of the bottle to start the suction. Do not hold the tongue when filling. Lors de l'utilisation automatique, the bottle must be placed under the discharge port, and the filling switch will be started as soon as the switch is turned on automatically, and the bottle will be replaced in time.

2. When the measurement is found to be unstable during filling, check the feed check valve for possible debris trapping, resulting in a tight seal and affecting the filling volume.

3. Leakage in the lower part of the cylinder body indicates that the piston seal is worn and needs to be replaced.

Heure de publication: 2020-03-21